Double-Head Vertical Strapping Machine: The Key to Enhancing Pallet Speed and Stability

How can pallet stability be enhanced during strapping? What solutions assist in reducing cycle time without compromising load containment? Innova Group’s double-head vertical strapping machine is an automatic strapping system designed to increase productivity and stability in pallet securing, especially on lines where loads require two straps per axis, or two or more straps in total.

This model complements Innova’s strapping range to meet the increasing market demand for a system with enhanced securing capabilities that ensure full load stability, while maintaining the quality and precision that characterize Innova Group’s packaging systems.

In this article, we will highlight the advantages and technical features of this innovative packaging solution.

Double-Head Strapping Model

The double-head vertical strapping system enables the simultaneous application of two straps per axis, which reduces cycle time and enhances load stability from the very first strap. Thanks to its synchronized operation, both straps are applied at the same time and with the same tension, ensuring uniform and secure containment, especially for loads that require multiple securing points per axis.

This system typically includes a pallet turner to strap the load on all four sides. In the case of volatile loads, it is essential to integrate a top press system to compact the load before applying the straps.

In which sectors is the double-head strapping system recommended?

The double-head system is essential for industries such as paper or cardboard, where loads require reinforced strapping because they are very light and unstable. In these cases, the system is typically combined with the pressing unit, ensuring a firmer and more stable finish.

On the other hand, it is also recommended for any industrial sector seeking to enhance productivity, as it significantly reduces strapping cycle time by applying two straps per axis simultaneously.

Advantages of Innova’s Double-Head Strapping System

This system provides many benefits for companies seeking to speed up the strapping process by offering a synchronized, accurate, and faster solution than the standard version.

1. Increased productivity

Thanks to its two simultaneously operating heads, this system can achieve a production rate of up to 60 pallets per hour, applying strapping to all four sides of the load. This significantly reduces cycle times compared to the standard version, which can reach a maximum of 35 pallets per hour.

2. Greater stability from the first strap

When straps are applied simultaneously with equal tension, the result is a more balanced and stable load, which is important for lightweight goods. This model prevents the load from shifting or becoming unstable, as might occur if the straps were applied one at a time.

3. Fixed strap spacing

The double-head system maintains a consistent distance between straps, which is crucial for the stability of certain types of loads. This ensures that the strapping meets the structural needs of the pallet accurately.

4. Strapping versatility with a shifter

The system can include a shifter mechanism to apply a third strap in a different position. For strapping across the width of the load (once the pallet has been rotated), the shifter allows the third strap to be applied at a strategically different point than the first two. Regarding the pallet’s length, the motorized transport system enables the load to move forward or backward to the desired position, ensuring that as many straps as needed can be applied.

Key Technical Features of the Double-Head System

The double-head is an innovative element in Innova’s strapping line, with technical features similar to the rest of the range but providing higher productivity:

Technical sheet FV|PRO – Double Head

- Production: Up to 60 pallets/hour

- Strap thickness: 8–12 mm

- Strap material: Polyester (PET) or Polypropylene (PP)

- Maximum load dimensions: 1,450 x 1,300 mm

- Maximum height: 2,000 mm

- Maximum load weight: 1,000 kg

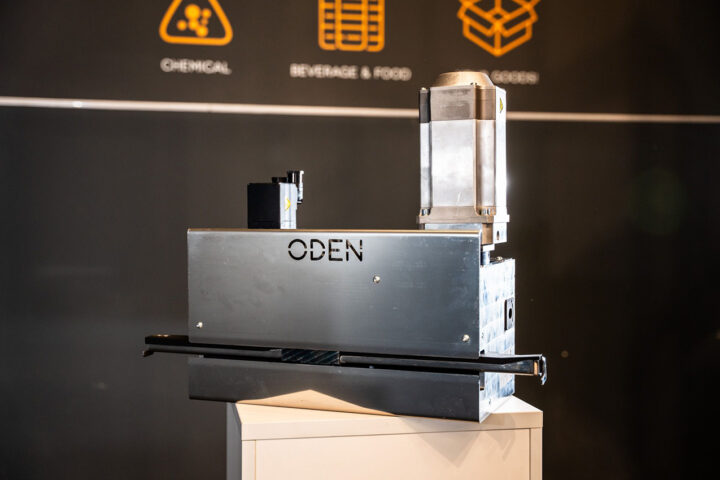

- Strapping head: ODEN strapping head patented by Innova. Resistance welding.

- Number of coils: 2 (one per head)

- Strap dispenser: Motorized with accumulator effect

Innovation Applied to Automatic Strapping

With this double-head system, Innova Group provides one of the most comprehensive automatic strapping ranges, aiming to meet the specific needs of various sectors and formats:

- Vertical pallet strapping system on 4 sides, with or without corner protector applicator

- Vertical strapping system with double head, with or without corner protector applicator

- Horizontal strapping system with 2 columns, with or without corner protector applicator

In short, with this innovative strapping machine, Innova Group reaffirms its commitment to innovation by offering solutions that combine performance and adaptability. If you would like more information on how this system can be integrated into your production line or wish to inquire about other packaging solutions, please feel free to contact our technical sales team. They will be pleased to assist you with your project to optimize and enhance your end-of-line operations.