How to meet the logistics packaging needs for chemical compounds

The chemical industry works with products of very diverse compositions, multiple formats, and different types of packaging, such as bags, big bags, or drums. In addition, materials such as polymers, solid powders, additives, frits, glazes, or petrochemical granulates require packaging systems that guarantee total protection and airtightness, intending to preserve product quality and ensure stability during transport and storage.

In this article, we analyze which packaging solutions meet the specific needs of the chemical sector and ensure the protection of palletized chemical compounds.

Needs and requirements of the chemical sector

The chemical sector works with products that are highly sensitive to contamination, which is why it requires packaging capable of completely isolating the load from external agents and keeping it hermetically sealed throughout the entire logistics process.

Added to this are strict industrial safety requirements, as facilities must minimize risks and comply with specific regulations due to the nature of the materials handled. In addition, the sector requires solutions that can adapt to different load formats, ensure proper product identification and traceability, and align with the industry’s sustainability objectives.

What packaging solutions does the chemical industry use?

Due to the wide variety of load formats and configurations within the chemical sector, packaging solutions must be able to adapt to each specific need. As mentioned above, the industry works with palletized loads of different heights and weights, and in this context, automatic stretch wrapping systems and Stretch Hood are the most widely used solutions due to their versatility and ability to adapt to any type of load and production level.

Stretch wrapping systems for the sector

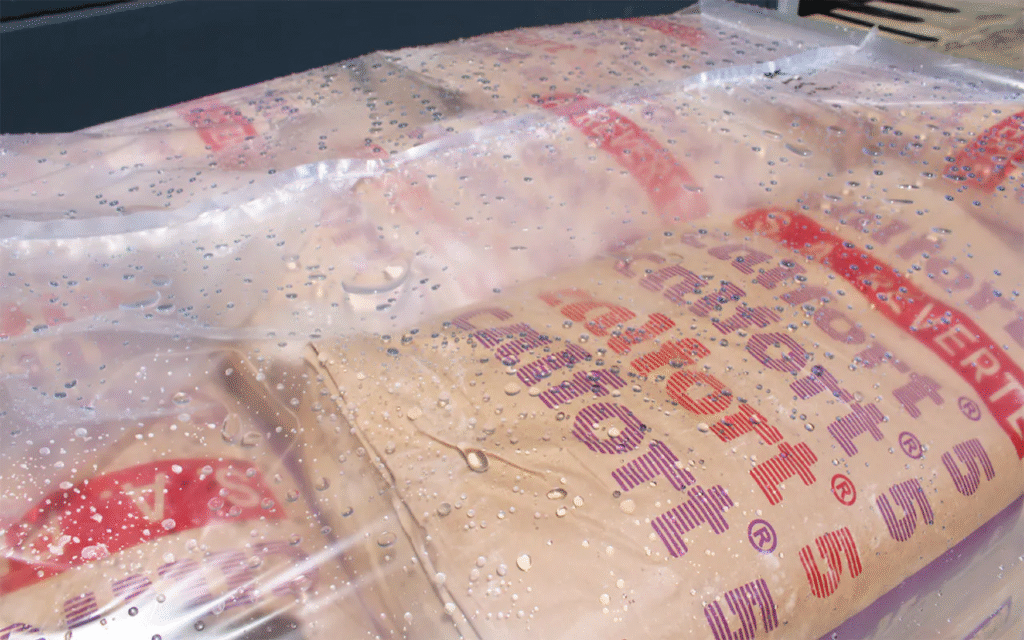

In the chemical industry, especially for products in bag format, stretch wrapping is one of the most commonly used solutions. Combining stretch wrapping with the application of a top cover allows the product to remain intact even in outdoor storage or demanding industrial environments.

As experts in this type of packaging solution, at Innova we design and manufacture automatic stretch wrapping systems tailored to the needs of the sector:

- Automatic ring stretch wrapping system: A high-performance solution designed to operate at high production volumes. It provides fast, uniform, and secure wrapping, ideal for chemical product bags that require firm load containment.

- Rotary arm stretch wrapper: Innova’s most versatile wrapper, thanks to its ability to adapt to any pallet type and size. A perfect system for chemical plants handling multiple product formats.

The modular design of both systems allows the integration of specific accessories such as edge protector applicators, top pressing plates, reinforcement roping systems, or cover applicators, further improving pallet stability and protection.

Stretch Hood: the best protection for chemical products

While stretch wrappers are an excellent solution for the chemical industry, Stretch Hood has established itself as the most advanced packaging solution for the sector, especially for products requiring a high level of protection and airtightness. Stretch Hood technology completely covers the load with a tubular film, sealing it on five sides and protecting it from dust, moisture, and other external agents.

What advantages does hooding offer?

1. 100% airtight protection

Stretch Hood hooding is the only system that provides total protection and airtight sealing, a critical requirement for the chemical sector due to the characteristics of the materials handled. With stretch wrapping systems, external agents may reach the product between film layers, or the film itself may lose a certain level of tension during extended storage periods.

2. Safe installation for chemical environments

Unlike other solutions that also offer a high level of protection, such as shrink hooding systems, Stretch Hood does not require gas installations for operation. This is a decisive advantage in the chemical industry to comply with strict safety regulations.

3. Adaptability to different formats

Stretch Hood stands out for its excellent adaptability to the various load formats commonly used in the chemical industry. It allows hooding of everything from bags to tall drum loads, big bags, or irregular pallet configurations. The elasticity and strength of the film provide a perfect fit around the load, ensuring both stability and protection.

4. Transparency and brand image

Another advantage over other systems is that the film layer is completely transparent and of superior quality, with no folds, wrinkles, or excess material. In addition to improving the presentation of chemical products, its transparency ensures that logos, labels, and codes are perfectly visible, enhancing traceability and connectivity.

5. Sustainability and material efficiency

Stretch Hood is a solution aligned with the sustainability policies of the chemical sector. By using a single layer of film to cover the entire load and requiring no heat for application, it saves up to 50% in consumables and significantly reduces energy consumption and CO₂ emissions. In addition, it is compatible with 100% recyclable films and films containing recycled content, helping chemical companies comply with environmental regulations and emission reduction targets.

In conclusion, the chemical sector requires packaging solutions that guarantee maximum protection, airtightness, and load stability. Automatic stretch wrapping systems and Stretch Hood effectively meet these demands, with hooding being the most advanced solution for products that require total protection.

At Innova Group, we design and manufacture packaging systems tailored to the specific needs of the chemical industry. Contact us and discover how we can help you achieve maximum efficiency at your end of line. Our technical team will be happy to assist you!