Checklist: Determine the Ideal Time to Upgrade Your Packaging System

Why should I replace my packaging system? How do I know if my equipment is obsolete? What benefits come from changing systems? Switching to a new packaging solution is not just a matter of the machine’s age, but of its ability to respond to current production, sustainability, and market competitiveness demands.

Today, the industry requires greater operational flexibility, high levels of automation, and superior final delivery quality. That is why the end of the line has taken on a strategic role within the supply chain, since an updated packaging system equipped with the latest market technologies can significantly improve any company’s logistics efficiency.

In this article, we outline the signs that indicate it is time to upgrade your packaging system and the key performance indicators (KPIs) that improve when this update is implemented.

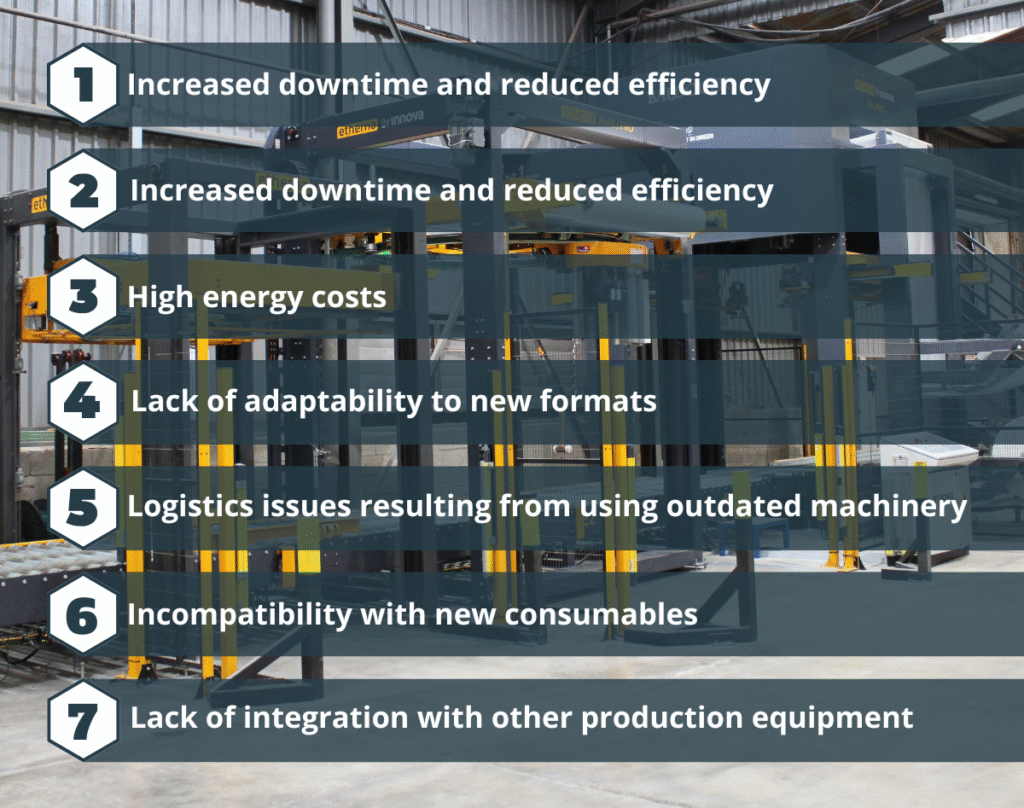

Clear Signs That Your Packaging System Is Obsolete

To know when to replace your packaging system, it is necessary to measure the system’s actual performance within the production process. Beyond the number of years the machine may have been in operation, several clear signs show when equipment has stopped being competitive:

Although most system upgrades are driven by productivity issues or problems with the machine itself, several indicators help us detect when the time has come.

1. Increased Downtime and Reduced Efficiency

If your system experiences continuous unplanned downtime due to maintenance, adjustments, or repairs, productivity and efficiency decrease proportionally. These interruptions are not only due to component wear, but also to unexpected breakdowns, lack of spare parts, mechanical misalignments, control system limitations, or incompatibility with new load formats and consumables—in other words, they are the consequences of operating with obsolete machinery.

2. Insufficient Production Capacity

When demand exceeds the speed or production capacity of the current system, bottlenecks are created. If the packaging line cannot keep up with production output, it is a clear sign that an upgrade aligned with market demands is required.

3. High Energy Costs

Another easy-to-detect sign is when energy consumption and operating costs skyrocket, as older packaging systems often have less efficient motors and components. Additionally, systems such as shrink wrapping require a gas installation and supply within the plant to operate, which also significantly increases electrical consumption. Systems like Stretch Hood, by using highly efficient motors and not requiring heat for application, significantly reduce energy consumption and CO2 emissions.

4. Lack of Adaptability to New Formats or Production Requirements

Today, many companies working with different pallet formats, variable heights, or mixed loads require flexible systems. If your end-of-line system cannot easily adapt to this type of production without constant stoppages, operator intervention, or additional costs, it is a clear sign of obsolescence.

5. Logistics Issues Resulting from Using Outdated Machinery

Older packaging systems can cause logistics problems due to load securing or stability failures. Load shifting, product damage, or packaging breakage are some examples. These incidents directly impact operating costs and customer perception of your brand.

6. Incompatibility with New Consumables

The evolution of packaging materials, such as films that allow higher pre-stretch percentages, requires equipment capable of working with these new features to maximize efficiency. If your current system is not compatible with these more advanced consumables or cannot fully leverage their performance, opportunities to optimize material usage, reduce costs, and improve end-of-line sustainability are lost.

7. System Obsolescence Due to Lack of Connectivity with New Production Equipment

Older systems may have difficulty communicating with next-generation machinery, advanced traceability systems, or AGVs, among others. This lack of connectivity hinders end-of-line integration into more digitalized environments and slows the transition toward Warehouse 4.0 models.

What Other Reasons Are There to Upgrade the End of the Line?

In addition to responding to signs of obsolescence, there are other strategic reasons to replace your system with a more updated solution adapted to new market demands.

- Improved packaging quality: Modern systems deliver a uniform and professional finish that enhances product quality perception and strengthens brand image factors increasingly valued by customers and distributors.

- More sustainable packaging: Technologies such as pre-stretch and customized wrapping cycles in automatic stretch wrappers, or the use of a single film layer to cover the entire load in Stretch Hood, align companies with industry sustainability goals. Additionally, recyclable and recycled consumables can be used.

- More advanced and safer technology: New systems are designed with simpler modular mechanics, decentralized electronics, and Industry 4.0 communication and control components for a safer process.

- Lower maintenance requirements: Next-generation machinery is designed with fewer wear components and simplified maintenance tasks, resulting in higher system availability.

Technical Analysis of Current Packaging System Performance

Despite the signs mentioned above, many companies continue using the same packaging system simply because it still operates. The reality is that even if a packaging system remains operational, it may no longer be competitive. At this stage, a technical analysis must be carried out to evaluate whether the current equipment meets the plant’s real production, cost, and efficiency requirements.

How can this analysis be performed? One of the best options is to analyze the key performance indicators (KPIs) of the current system and compare them with the improvements that would result from installing a next-generation packaging solution.

Which KPIs Improve with a Next-Generation End-of-Line System?

Upgrading the packaging system directly impacts several key performance indicators. Among the main KPIs that improve are:

- System availability, thanks to reduced unplanned downtime.

- Productivity, by increasing packaging speed and eliminating bottlenecks.

- Cost per pallet and sustainability, through lower energy and consumable consumption.

- Logistics incidents, reducing damage, claims, and returns associated with packaging.

However, it is important to highlight the two KPIs that are gaining increasing importance in the industry:

- OEE (Overall Equipment Effectiveness): Measures the overall efficiency of equipment by combining availability, performance, and quality. An OEE below 70% usually indicates significant inefficiencies. An OEE of 65% can reach up to 80% after installing a next-generation system, thanks to reduced downtime, increased speed, and improved packaging quality.

- ROI (Return on Investment): Systems such as Stretch Hood can achieve payback within 6 to 12 months. If you need to calculate ROI accurately, Innova offers a free savings study that analyzes the actual payback of each packaging project.

In short, the time to upgrade your end-of-line system comes when the packaging system no longer meets market demands. When productivity, energy efficiency, or packaging quality are compromised, the end of the line becomes a limiting factor for company competitiveness. A next-generation packaging system allows you to optimize plant performance, reduce operating costs, and align with current environmental standards.

At Innova, we analyze each project individually and design advanced packaging solutions capable of transforming your end-of-line performance. Contact our technical-sales team and discover how we can help you optimize and improve your packaging line.