7 keys of Stretch Hood packaging system for the agrifood industry

Feed, cereals, grains, fertilizers and other agrochemical and agrifood compounds: All these products require total protection in storage and transportation. The search for the protection is one of the main reasons the sector is increasingly relying on innovative pallet packaging solutions such as Stretch Hood. With a single layer of film, the pallet of agri-food product is fully wrapped, protected and safe for handling and storage. Discover in this article the 7 most important keys of Stretch Hood protection for agrifood.

We affirm that Stretch Hood is one of the most advanced systems for total pallet protection as it performs a cold wrapping with a stretchable tubular film that adapts and covers the entire load. Unlike other packaging solutions such as the wrapping system, with a single layer of film the product is protected without the need for additional plastic layers or a cover for the top.

Let’s look at some of the specific advantages for the agri-food sector:

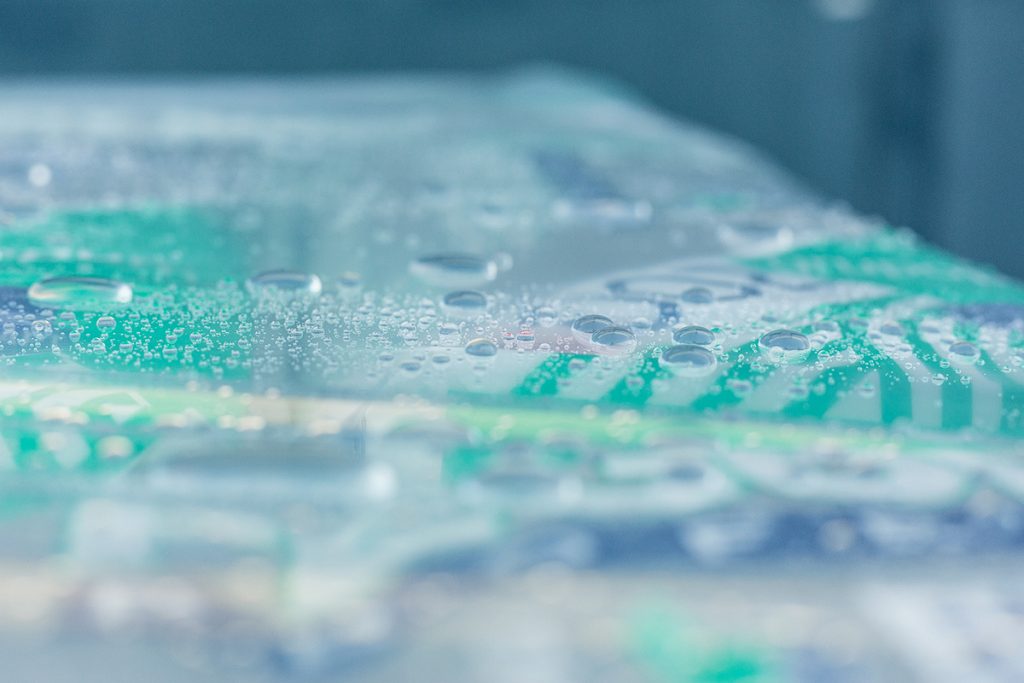

1. Total watertightness of the product

Stretch Hood fully adapts to the product, sealing it completely and leaving it completely waterproof against moisture, rain or other external agents. In addition to the watertightness provided by the wrapping itself, the Stretch Hood film has very specific properties that provide waterproofing. In the specific case of the agri-food product, this is an indispensable requirement as it prevents the product from being affected by humidity or rain during storage and transport. The properties of Stretch Hood film also provide better hygiene in the final packaging for bags of feed, cereals, seeds, etc.

2. Maximum product protection

In addition to total waterproofing and sealing of the product, Stretch Hood provides total protection against external agents in general. Apart from the humidity, the most common agents that affect the agri-food product are dust caused in storage or direct action of the sun in cases of outdoor storage. In this case the film includes in its properties an anti UV barrier to protect the agrifood product.

3. Savings in consumable costs

According to studies carried out by Innova, the Stretch Hood system can reduce film consumption by up to 50% compared to other solutions such as the wrapping machine. Compared to the shrink-wrapping system, Stretch Hood saves even more on consumables since it does not need to use gas in shrink-wrapping, and uses a lower amount of film than the shrink-wrapping system. According to our own analysis, Stretch Hood’s investment can be redeemed within 1 to 2 years regarding solutions previously used as shrink-wrap.

4. Greater automation of the packaging process

For agri-food companies, the Stretch Hood system also represents a breakthrough in packaging automation and a step towards Industry 4.0. The Stretch Hood packaging line consists of the wrapping solution plus strapping and transport complements that are fully integrated with the end of line of the agri-food processing plant or other existing systems. In addition, the line enables connection to intelligent warehouses, as well as remote connection and diagnosis of incidents.

5. Higher wrapping speed

Compared to other semi-automatic solutions or systems such as shrink-wrapping, Stretch Hood also accelerates the final packaging of agrifood companies. In fact, the Innova SH Pro2 S2 model can wrap at a speed of 150 pallets/hour. Even if the production of a fertilizer or feed company does not have this palletizing speed, this means that the Stretch Hood system performs more than 2 pallet wrappings per minute, saving on the energy used and allowing a more efficient packaging.

6. Flawless presentation and better brand image

For many agri-food companies, the image of their products is paramount in the delivery to the customer. In this case the Stretch Hood system provides an impeccable final packaging, with a completely transparent film, without folds or wrinkles usually caused by other systems. The transparency of the Stretch Hood system is also highly valued for the legibility of codes enabling better traceability for transport and logistics.

7. The most sustainable packaging system

Last but not least, Stretch Hood brings an increasingly important advantage, as it is the most sustainable and energy-efficient system. For agrifood companies, the environmental concern is already reflected in their production policies and presentation of their products. Using Stretch Hood, these companies can contribute to the care of the planet by reducing CO2 emissions, plastic consumption and the energy used in packaging. We also recommend the use of recyclable and biodegradable Stretch Hood film, a difficult requirement to find with other types of film.

In summary, Stretch Hood is one of the most advanced systems for the final pallet protection of agricultural and agri-food products. Packaging for transport and storage is already a key to increase competitiveness and efficiency in the sector and more and more companies are opting for technologies such as Stretch Hood. This is evidenced by Innova’s customers in the sector with whom we have improved their packaging efficiency and protection of their products, with a solution that also protects the environment.

#WeAreYourPartner

#WeAreInnova