FMCSA Normative in the US: How to Secure Cargo During Transportation

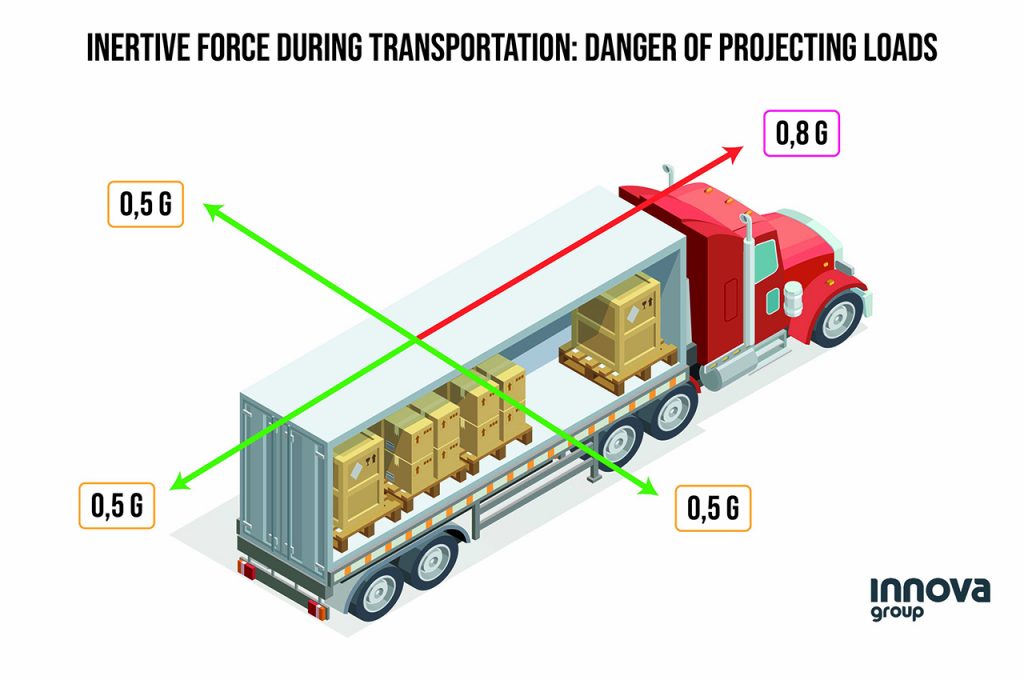

There are many ways in which cargo can be damaged during transport: either by bad weather conditions, poor securing or poor road conditions, or even the breakdown of security systems during transportation. This results in huge economic and time losses, as well as harm to public safety. By addressing these causes through training, implementing best practices, and ensuring proper enforcement, companies can significantly reduce the prevalence of these bad practices and promote the safety of everyone on the road.

In this article, we will discuss the most common errors in securing cargo and how to prevent and improve load support and protection practices.

What is the FMCSA Normative about US Cargo Standards

The FMCSA published the North American Cargo Securement Standard, which establishes procedures for securing loads during transit on highways in the U.S., Canada, and Mexico: “Cargo securement systems on or within vehicles should prevent their cargo from leaking or spilling, blowing off or falling from or through the vehicle, or becoming dislodged from its storage location. Cargo should not be allowed to shift within an enclosed vehicle or adversely affect the vehicle’s stability. In brief, cargo that is unsecured or improperly secured can be dangerous to the driver, the vehicle, and everyone else on the road. By following the proper cargo securement guidelines by the FMCSA, drivers can ensure their cargo gets to its destination safely and intact without posing a risk to anyone else.”

According to this standard, the loads must be properly wrapped at the factory, and once on the truck, they must be positioned and secured correctly. Proper cargo securement is essential to ensure the safety of drivers, other vehicles on the road, and people nearby. Unsecured cargo can fall, shift, or leak, causing accidents and injuries.

Common Cargo Securement Mistakes and How to Avoid Them

Performing a thorough safety check before transportation can prevent many problems. The FMCSA has identified common errors to avoid:

- Failure to prevent shifting/loss of load

- Failure to secure truck equipment (tarps, dunnage, doors, tailgates, spare tires, etc.)

- Damaged tie-downs (unacceptable wear on chain or cuts and tears on web straps)

- Insufficient tie-downs

- Loose tie-downs

All of these situations can have severe economic and legal consequences. Here are some steps you can take to secure the load and to prevent these cases:

- Use the right equipment: Choose tie-downs, straps, and dunnage (material used to fill gaps and prevent movement) appropriate for the weight, shape, and friction of your cargo.

- Inspect equipment: Ensure tie-downs and straps are not frayed, worn, or damaged. Replace any faulty equipment before loading.

- Secure evenly: Distribute the weight of the load evenly across the transport area.

- Tie-down techniques: Use proper tie-down techniques to create a secure hold on the load. This may involve using a basket weave pattern for multiple straps or following specific guidelines for different cargo types.

- Friction mats: Consider using non-skid mats under the load to increase friction and prevent shifting.

Cargo Considerations: Securement Methods for Different Load Types

While the core principles of cargo securement remain consistent (using tie-downs, dunnage, and proper weight distribution), the specific methods used can vary depending on the type of cargo being transported. Here’s a brief overview:

- Palletized Goods: Use tie-downs with a WLL exceeding the weight of the pallet and its contents. Employ a “basket weave” pattern for multiple straps to ensure stability.

When palletizing a load, it’s essential to ensure that it’s securely fastened to both the pallet base and itself. To achieve this, you can use either pallet stretch wrapping or pallet strapping packaging systems. For instance, with a vertical strapping system the load can be fixed to its pallet base, providing a greater stability and fixation of the load. Meanwhile, the Stretch wrapping it’s used to unite the base of the load with the pallet by means of a reinforcement wrapping or the use of the roping system.

Considerations: Ensure pallets are in good condition and stacked evenly. Use edge protectors for strapped pallets to prevent strap wear on the boxes.

- Liquids: Liquids must be in secure and leak-proof containers suitable for transportation. Use IBC tanks (Intermediate Bulk Containers) with proper tie-downs or cradles specifically designed for liquid containers. Wedge dunnage can be used to fill gaps and prevent movement.

Considerations: Check for leaks or damage to containers before loading. Label hazardous liquids appropriately.

- Loose Items: Use strong, secure boxes, crates, or netting to contain loose items and prevent them from shifting or falling out. Palletless loose items can be secured using a combination of tie-downs, dunnage (to fill voids), and secure coverings (tarps) to prevent windblown debris.

In this case, using Stretch Hood or Stretch Wrapping is recommended to ensure secure fastening to both the pallet and itself, similar to palletizing goods.

Considerations: Pay close attention to weight distribution for loose items to prevent them from becoming unbalanced and causing tipping.

Additional Considerations:

- Fragile Items: Use additional cushioning materials (bubble wrap, foam peanuts) within boxes for fragile items to absorb shock and prevent breakage.

- Heavy Machinery: Heavy machinery often requires specialized cradles or blocking systems to ensure secure transport. Consult with a professional for proper securing methods for oversized or heavy equipment.

Other factors to ensure cargo securement

You have to also prepare the vehicle. It is important to know the weight limits and the vehicle’s condition but also try to keep an eye on how is manipulated the cargo during the loading and unloading. Many damages are due to bad manipulations during that process.

The load can move and bounce against the truck walls and be damaged, which is why The FMCSA also recommends the use of edge protection “whenever a tiedown would be subject to abrasion or cutting at the point where it touches an article of cargo. The edge protection must resist abrasion, cutting and crushing”.

At Innova, we provide an automatic edge protector applicator system as an accessory for our all of our packaging systems such as the strappers, the stretch wrappers and even the stretch hood system. With the edge protectors, the load is not only protected, but it also compacts the load and improves the presentation of the merchandise to the customer.

Another important aspect is that, whether the cargo is protected inside the truck, sometimes the load arrives at the destination in a few days, but other times, the truck can take weeks. That’s when humidity or dust can reach and cause (albeit to a lesser extent) damage to the load.

The Stretch Hood system is an effective way to protect and secure your load. It fits perfectly onto the pallet and the shape of your products, ensuring complete protection from external elements like dust, rain, and humidity. By using this system, you can save both money, storage space and avoid product losses due to damaged goods under hard weather conditions.

Best Practices Before, During, and After the Transport

To make sure the truck, the load, and all the securing systems and accessories are in perfect state, we recommend the following tips & tricks:

- Staff training: Provide proper training to those responsible for loading and securing cargo.

- Security signage: Use signage on the vehicle to indicate weight limits and any special handling instructions.

- Laws and regulations: Be familiar with the laws and regulations regarding load securement in your area. These can vary depending on the type of vehicle and cargo. For specific guidelines and regulations, consult resources from your local Department of Transportation or trucking associations.

- Pre-trip inspections: Make a pre-trip inspection part of your routine to check the security of all truck equipment, including tarps, dunnage, doors, tailgates, spare tires, and tie-downs.

- Driver training: Train drivers on proper procedures for securing truck equipment and the importance of regular inspections.

- Reporting procedures: Establish a clear reporting system for drivers to notify maintenance personnel of any damaged or missing tie-downs. This ensures prompt replacement and prevents them from being used inadvertently.

- Maintenance schedule: Maintain a regular maintenance schedule for your truck to address any potential issues with latches, hinges, or other equipment securing mechanisms.

By following these practices, you can significantly reduce the risk of unsecured truck equipment causing damage or creating safety hazards on the road.

In short, improving the safety of loads is a major concern for our customers, and that is why Innova’s automatic packaging systems are designed to optimize the stability of the load while reducing consumables and energy costs. Do not hesitate to consult with our technical team and we will recommend the best systems to improve the safety and protection of your precious goods.

SUBSCRIBE