How to secure and protect the ceramic load of large formats?

The trend of large ceramic formats has entered the construction and decoration market to stay. New interior projects and refurbishments are increasingly opting for large format pieces for their functional and decorative advantages. This is why most ceramic manufacturers offer these formats in their collections. In today’s article we will analyse this trend from a logistical point of view, outlining the main problems in the transport of large format boxes and the best packaging solutions to secure and protect these very special ceramic loads.

What is large format tile?

Manufacturers and decorators are opting for large formats in both wall and floor coverings. Apart from special large XXL formats, it is more common in the market to offer large formats such as 80×80, 45×90, 60×120 or 120×120 cm, among others. These are formats that are increasing their presence in the ranges of proposals of manufacturers and interior designers as they are suitable measures for any reform, providing width to the space they cover.

As far as logistics are concerned, this type of format can present a major challenge when handling and transporting, as these boxes are not so standard in the ceramics sector. The best formula to protect this type of special product is to combine several palletising and packaging systems to secure and protect the large format ceramic pallet as much as possible.

Which problems are usually caused by the transport of these formats?

The most common problems with this format are usually related to the hold of the product:

– Poor load stability in transport, due to palletisation and improperly fixed, e.g. with formats such as 60 x 120.

– Load displacement, due to low stability or lack of compaction of the block load.

– Cracks in the ceramic boxes, if the pallet strapping is carried out at a higher tension to avoid displacement, it may damage the edges of the ceramic boxes.

Which packaging systems better protect the large format ceramics?

The best fixing solution is the combination of several pallet packaging systems for ceramic. Below we analyse our best systems for large format ceramic projects:

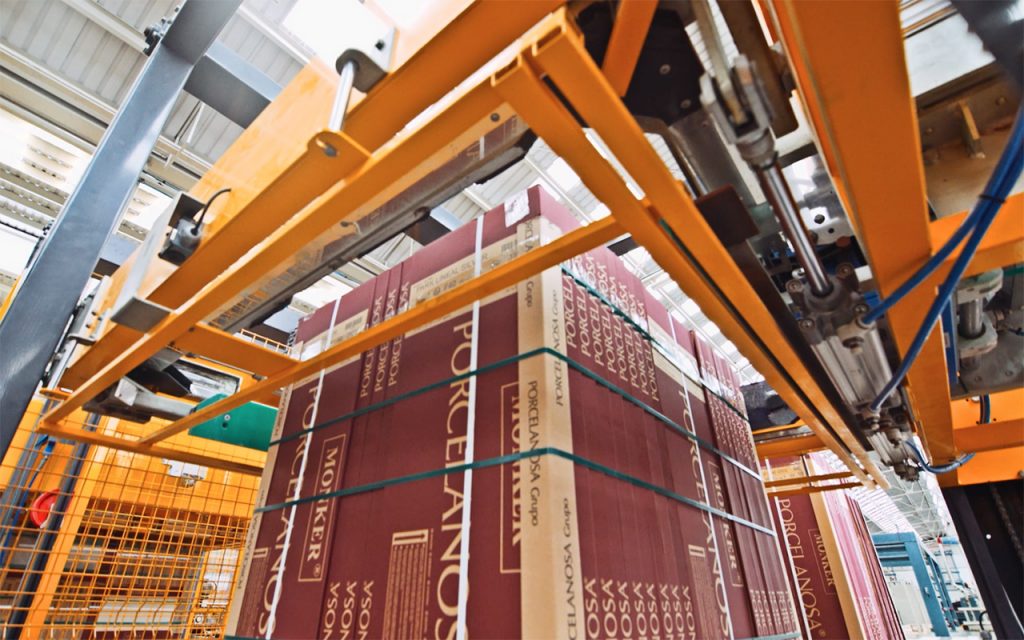

– Horizontal strapping machine: Block holding and compacting

Horizontal pallet strapping is used to compact the load and hold it in a whole block. In addition, Innova´s automatic strapping machine incorporates a compactor that aligns and compacts the load prior to strapping. Pallet strapping is one of the most important solutions to prevent boxes from moving or breaking.

– Vertical strapping machine: Holding and unification of the load with the pallet base

Vertical strapping is also used for securing, but with the aim of uniting the load with the base of the pallet, achieving greater stability in transport. It is usually recommended that the two types of pallet strapping be combined to obtain this total subjection.

– Automatic pallet wrapping machine: Wrap-around load fastening

For large format loads the pallet wrapper is a very efficient packaging solution as it provides a grip adapted to the load environment. The application of cord acts as an extra fastening similar to strapping and its wrapping also reaches the pallet, thus unifying the ceramic load with its base for transport. This type of packaging system is presented as an alternative to the vertical strapping system as it provides grip and hold with the pallet.

– Stretch Hood wrapping system: Fixing and protection against external agents

Finally, the Stretch Hood packaging system provides additional support to that of the pallet strapping machine or the pallet wrapping machine, as the hood stretches and adapts to the contour of the load. The main advantage of Stretch Hood is that it offers maximum protection for the special load, sealing it from external agents such as rain, dust etc. In addition, Stretch Hood film contains UV barrier properties for outdoor storage.

We also recommend other packaging accessories for large formats:

– Pallet strapping system with edge protector applicator: Protection of the boxes from being strapped

Incorporating edge protectors into the pallet strapping process (either horizontal or vertical) will ensure that the boxes are protected from strapping tension. Corner plates are especially recommended for large or special format boxes as they will reduce the impact of the strapping on the box, avoiding cracks or marks on the box. For this purpose, we recommend the automatic Edge Protector applicator incorporated in the pallet strapping system.

– Automatic sealing system: Securing the boxes at the point of sale

The box sealing system is a complement for special formats and vertical palletisation of large-format boxes. The seal ensures the cohesion of the top of the boxes and prevents them from collapsing when the strap is removed at the point of sale.

In short, the optimal combination of several of these end of line packaging systems for is the solution to better secure large-format ceramic loads. In fact, several of our customers already work in their end of line with Innova solutions for large format with several of the systems mentioned in the article. In each project, our technical team carries out an exhaustive study to define the best packaging line according to the customer’s production formats. Do not hesitate to contact us for more information or to request a packaging study, we will be happy to assist you!

#WeAreInnovaTech

#WeAreYourPartner