Top 10 Frequently Asked Questions about the Automatic Ring Stretch Wrapper

The automatic ring stretch wrapper is one of the most widely used packaging solutions at the end of the production line in many industries. It is a system known for its versatility, load protection, and high production speed. At Innova Group, as manufacturers specializing in packaging solutions, we address the most common questions we receive about this system. Following our Top 10 FAQ series, we explain how it works, its benefits, and why it is the best solution for your end-of-line packaging needs.

The Top 10 FAQ of the Ring Stretch Wrapper

- How does an automatic ring stretch wrapper work and what advantages does it offer?

- What level of productivity can it achieve?

- What types of cycles can it perform?

- How much film does the ring wrapper consume?

- What technologies does this system incorporate to optimize film consumption?

- What accessories can be added to improve the wrapping process?

- Can it be integrated into existing automatic lines?

- What maximum dimensions, height, and weight does the wrapper support?

- How much space does the system require for installation and proper operation?

- What maintenance does the automatic ring stretch wrapper require?

1. How does an automatic ring stretch wrapper work, and what advantages does it offer?

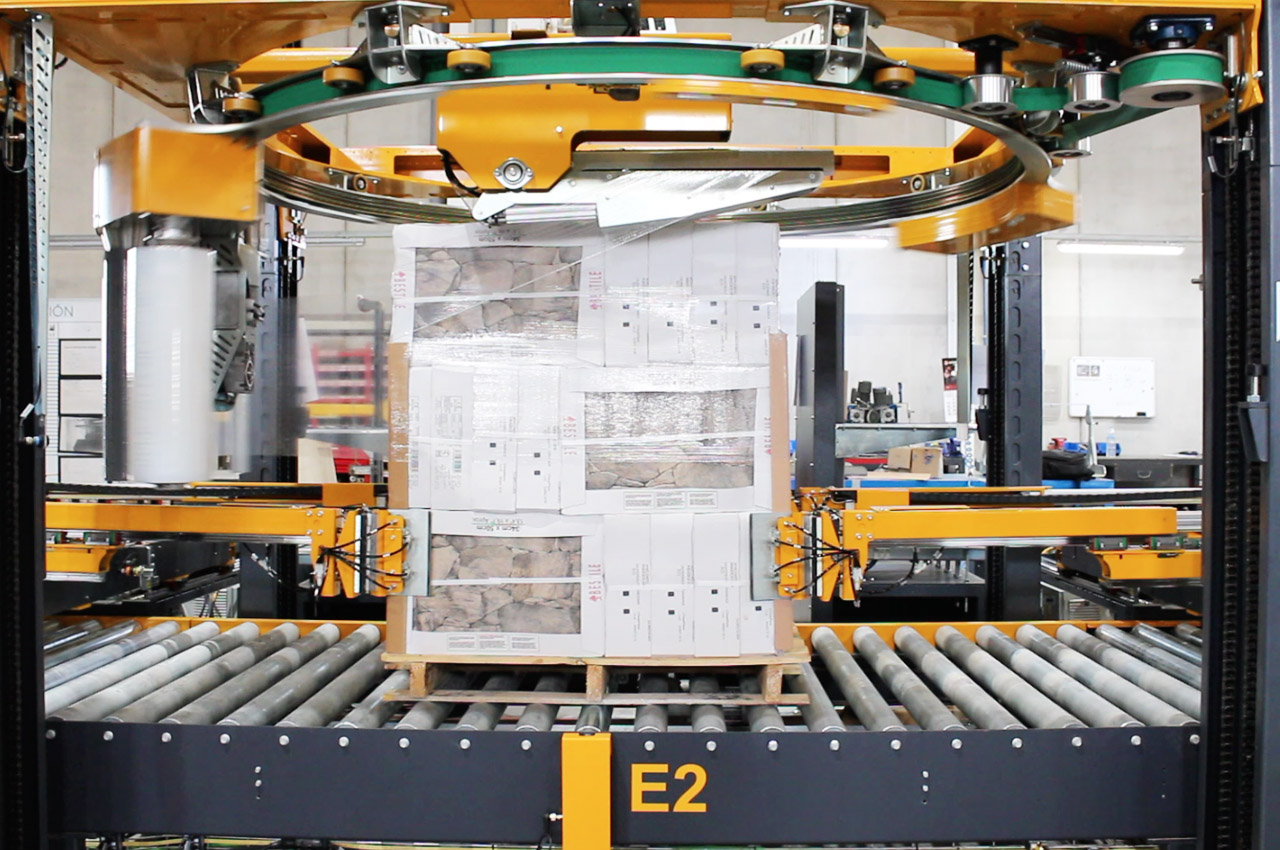

The ring wrapper is a high-performance stretch wrapping system that applies stretch film by means of a rotating ring that surrounds the load while the pallet remains stationary, wrapping it in a continuous, precise, and uniform manner.

One of its main advantages is its high productivity without compromising load stability. Since the pallet does not move during the process, the ring stretch wrapper is especially suitable for tall, unstable, or fragile loads, ensuring safe wrapping at high speeds. In addition, the option to incorporate a dual film carriage allows production to be increased and cycle times to be optimized.

2. What level of productivity can it achieve?

This automatic system is designed to operate with high production volumes. In standard configurations, the ring wrapper can reach up to 60 pallets per hour with a single film carriage, delivering high and consistent performance. However, its maximum potential is achieved with the dual-carriage system, as adding a second film carriage increases system productivity to up to 80 pallets per hour.

3. What types of cycles can it perform?

Depending on the type of load and product, customized cycles can be programmed with different tension levels, number of wraps, and reinforcements in specific areas of the pallet. Some of the most common cycles include:

- Base reinforcement: Focuses on reinforcing the securing of the pallet base, either with additional film layers or by means of a reinforcement rope. This cycle is especially useful for light or unstable loads.

- Top reinforcement: In the case of tall loads, a cycle can be configured to cover the entire load with reinforcements in specific areas, particularly at the upper film overlap.

- Reinforcement rope: A system that transforms the film into an elastic rope that acts as a horizontal strap, providing extra security and compaction without damaging the product.

It should also be noted that another advantage of this system is its flexibility at the start and end of the cycle, as wrapping can begin from the base, the top, or an intermediate area of the pallet, adapting to different load formats and logistical requirements.

4. How much film does the ring stretch wrapper consume?

Film consumption in a ring wrapper depends, among other factors, on load dimensions, the required level of load securing, and the selected cycle. To provide an approximate reference, we will consider Euro pallet dimensions (1,200 x 800 mm).

Consumable usage is approximately 13 grams per pallet, which translates into around 200 pallets per film roll, always referring to approximate values.

5. What technologies does this system incorporate to optimize film consumption?

This system is designed to maximize stretch film optimization. It incorporates a motorized pre-stretch system that, when using high-quality film, allows stretch ratios of up to 400%, significantly reducing the amount of material used.

In addition, torque control technology ensures consistent and precise film application, regulating tension throughout the entire wrapping cycle to prevent breaks and material waste. This is further enhanced by the ability to program customized wrapping cycles, applying reinforcements only where necessary.

6. What accessories can be added to improve the wrapping process?

The ring stretch wrapper is a highly versatile system that, thanks to its design, can include a wide range of accessories to enhance wrapping according to load requirements.

Some of the most common accessories include:

- Edge protector applicator: Vertical edge protector for special loads that require extra protection on their edges.

- Top cover applicator: For loads that require total protection, a top cover made from a specific consumable is applied, designed to provide additional protective properties and overlap with the main wrapping.

- Top holding press: A system that holds unstable loads during the wrapping process to prevent displacement.

7. Can it be integrated into existing automatic lines?

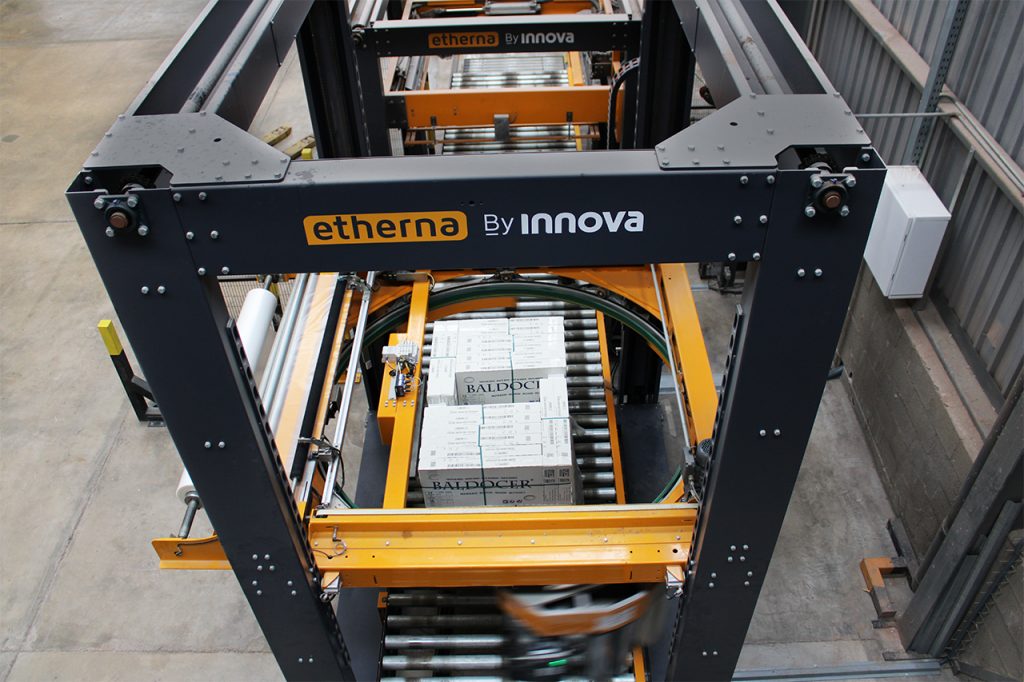

The automatic ring wrapper is designed to be easily integrated into automatic packaging lines, both in new projects and in existing lines. Thanks to its modular design and advanced PLC control, it can be aligned with other line equipment such as strapping systems or Stretch Hood, forming part of a fully automated end-of-line solution.

8. What maximum dimensions, height, and weight does the wrapper support?

Before installing a ring stretch wrapper, it is important to understand the load limits it can handle.

In the case of the Innova ring wrapper, the specifications are:

- Maximum load dimensions: Formats up to 2,000 mm (L) x 1,200 mm (W)

- Maximum height: Up to 2,500 mm

- Maximum weight: 2,000 kg (adaptable depending on the conveyor motor)

These dimensions can be adapted to the specific needs of each project, depending on the type of load, pallet format, and packaging line configuration.

9. How much space does the system require for installation and proper operation?

The space required to install an automatic ring wrapper depends, as with other systems, on load characteristics. For standard pallet formats of 1,200 x 800 mm, the ring wrapper requires approximately 3 meters in length, 3 meters in width, and 4 meters in height. The overall system height may vary depending on pallet height and can reach up to 5 meters in the case of tall loads.

10. What maintenance does the automatic ring stretch wrapper require?

The automatic ring wrapper, like any packaging system, requires a preventive maintenance plan to ensure optimal performance and extend its service life. It is essential to carry out periodic inspections that include basic routines such as component cleaning, lubrication of moving parts, mechanical adjustments, safety system checks, and software updates. These actions help prevent premature wear, reduce the risk of breakdowns, and optimize system performance.

In conclusion, the automatic ring stretch wrapper is one of the most advanced packaging solutions, fully prepared to meet the demands of high-production industrial environments. Its design allows for wrapping unstable, large-format, and tall loads while ensuring uniform load securing and a high-quality finish.

At Innova Group, we design and manufacture packaging systems such as the ring wrapper, tailored to the specific needs of our customers. Contact us and discover how we can help you achieve maximum efficiency at your end of line. Our technical team will be happy to assist you.