Top 10 Most Frequently Asked Questions About Vertical Pallet Strapping Systems

Improving load stability and securing goods during transport and storage is one of the main concerns in the industry, and the automatic vertical pallet strapping machine is one of the most effective solutions. However, questions often arise regarding how it works and the advantages it offers. At Innova Group, as manufacturers specializing in packaging systems, we want to address these questions. In this article, we answer the top 10 most frequently asked questions (FAQs) we receive about this system.

Top 10 FAQs About the Automatic Vertical Pallet Strapping System

- How does a vertical pallet strapping system work and what advantages does it offer?

- What accessories can be added to improve strapping?

- What production capacity does it have?

- What types of strapping are available and what are their characteristics?

- How is the strap sealed?

- Can it be integrated into existing automatic lines?

- What maximum dimensions, height, and weight can the vertical strapping machine handle?

- How can you save on strapping consumables?

- How much space does the system require for proper installation and operation?

- What maintenance does the vertical strapping machine require?

1. How does the vertical pallet strapping system work and what advantages does it offer?

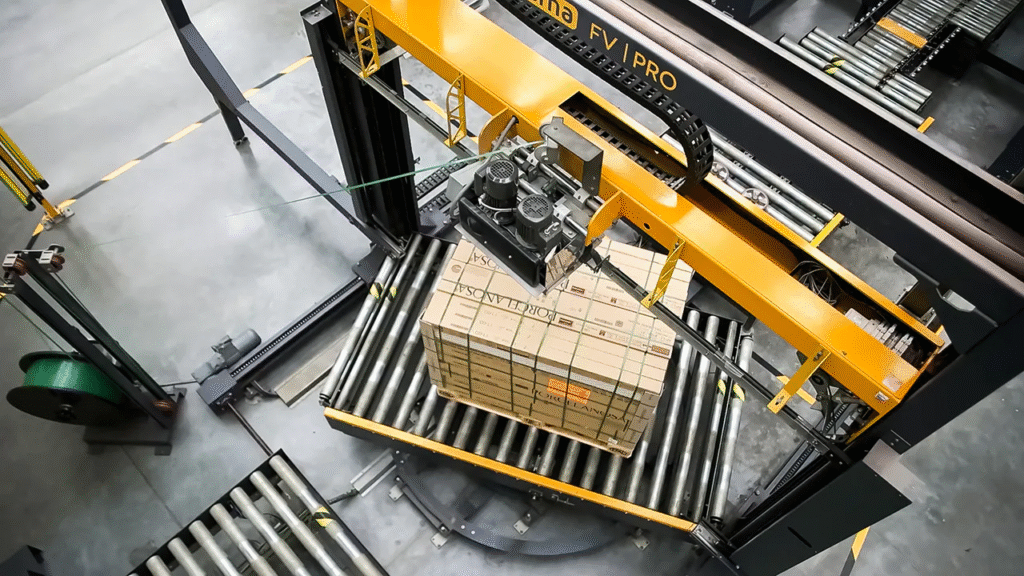

The automatic vertical strapping system secures the load directly to the pallet base, creating a compact and stable unit that reduces the risk of load shifting. The system applies the strap vertically with controlled and uniform tension, ensuring a firm fixation without deforming the product.

Main advantages of vertical pallet strapping:

- Greater load stability: Vertical strapping secures the load directly to the pallet, significantly reducing the risk of movement, even with light or unstable loads.

- Reduced product damage: By fully securing the load, the effects of vibrations, impacts, and sudden movements are minimized, protecting both the boxes and the final product throughout the entire logistics process.

- Improved safety during handling and transport: Properly strapped loads improve safety during transport, storage, and handling operations, reducing the risk of incidents and accidents caused by unstable pallets.

2. What accessories can be added to improve strapping?

Vertical strapping systems can be equipped with a wide range of accessories, both to enhance machine performance and to increase load protection. Some of the most common accessories include:

- Edge protector applicator: This system applies cardboard edge protectors to the horizontal edges of the load prior to strapping, improving load unitization and compaction while also protecting the load from damage caused by the strap itself.

- Lateral displacement system: This accessory allows the strapping arch to move laterally, applying the strap in the required position without moving the pallet—especially suitable for fragile or unstable loads.

- Dual strapping head: Allows two straps to be applied per axis simultaneously, reducing cycle time and improving load stability.

- Pressing system: Designed to compact the load before strapping. This accessory is especially useful to prevent load shifting in light or unstable loads, such as stacked paper or cardboard.

- Foldable lance system: Reduces the footprint of the system on the production floor. The lance is positioned vertically only during the strapping process and remains folded down the rest of the time. It is particularly useful in space-restricted lines and for wide pallet formats that require a longer lance.

3. What production capacity does it have?

The production capacity of a strapping system is directly related to the number of straps applied. In a standard system that applies two straps around all four sides of the pallet, typical output can reach 30 pallets per hour.

However, by applying the same number of straps and incorporating a dual-head system, the straps can be applied simultaneously, reducing cycle time and increasing productivity to up to 60 pallets per hour.

4. What types of strapping are available and what are their characteristics?

Automatic strapping systems mainly use two types of strapping: polypropylene (PP) and polyester (PET).

- Polypropylene (PP): Polypropylene is a thermoplastic polymer that combines strength and elasticity, making it one of the most commonly used materials for securing palletized goods. It also stands out for its resistance to moisture and external agents.

- Polyester (PET): Polyester is a high-strength plastic resin. PET strapping is more rigid than polypropylene, with lower elongation and excellent long-term tension retention.

Both types are available in standard widths of 9, 12, and 16 mm, with typical thicknesses of 0.6 and 0.75 mm. The choice between PP and PET depends on the required level of load retention, load weight, and transport and storage conditions.

Other types of strapping include steel strapping, which is significantly more expensive than PP or PET, and textile strapping, which is usually applied manually using a tensioning tool.

5. How is the strap sealed?

Strap sealing can be performed using different welding techniques, depending on the characteristics of the strapping head:

- Vibration or friction welding: Sealing is achieved through a vibrating motion that generates heat, allowing the strap ends to be joined under pressure.

- Resistance welding: This method also uses heat, applying a controlled electric current directly to the strap. The strapping head automatically regulates temperature and cooling time, ensuring a uniform and secure seal.

- Ultrasonic welding: This technology transmits mechanical vibrations under pressure to the strap ends, compressing and bonding them to create an extremely strong, consistent, and fast seal.

6. Can it be integrated into existing automatic lines?

Innova’s vertical strapping machine is designed to be integrated into automatic lines alongside complementary packaging systems such as automatic wrapping machines or Stretch Hood, forming part of a complete end-of-line solution. Thanks to its modular design and advanced PLC control, it can be synchronized with the rest of the line equipment, optimizing pallet flow and ensuring continuous production without bottlenecks.

7. What maximum dimensions, height, and weight can the vertical strapping machine handle?

Before installing an automatic strapping system, it is important to know the load limits it can handle.

For Innova’s vertical strapping machine, the specifications are:

- Maximum load dimensions: (L) 1,300 x (W) 1,250 mm

- Maximum height: from 300 mm to 1,500 mm (up to 2,500 mm in 500 mm increments)

- Maximum weight: 2,000 kg

These dimensions can be customized based on the specific requirements of each project, depending on load type, pallet format, and packaging line configuration.

8. How can you save on strapping consumables?

Strapping systems are a cost-effective load-securing solution, as full load stability can be achieved with a small number of straps and minimal consumable usage. Even so, further optimization is possible:

- Using the correct strap for each load: For example, if extremely high load retention is not required, there is no need to use steel strapping—PET or PP straps offer sufficient holding force, greater elasticity, and lower cost.

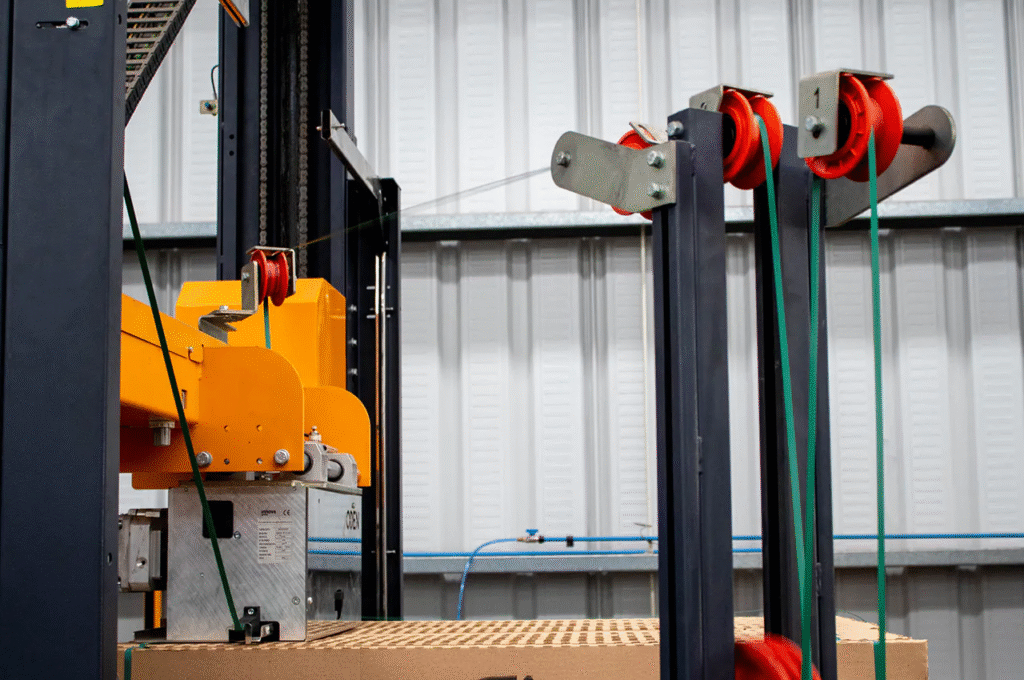

- High-precision strapping heads: Using state-of-the-art strapping heads ensures precise tension control and reliable sealing, preventing strap breakage and material waste. At Innova, we work with our own patented ODEN strapping head, a compact, modular, high-performance system.

9. How much space does the system require for proper installation and operation?

The space required to install an Innova vertical strapping system depends on the line configuration and whether it is a complete new installation or an integration into an existing line.

For a complete vertical strapping line—including pallet infeed with centering system, conveyor with turntable for four-side strapping, and an accumulation and discharge line—approximately 10 meters in length and 4.5 meters in width are required. In configurations without a turntable, the length can be reduced to around 9 meters.

When integrating the system into an existing automatic line, the required space is smaller: approximately 3 meters in length for systems without a turntable and 6 meters when a 90-degree transfer conveyor is included for four-side strapping.

10. What maintenance does the vertical strapping machine require?

The automatic vertical strapping machine requires basic preventive maintenance, including cleaning the strapping head, checking the welding system, and periodically inspecting moving components. Its robust design and easy access to components help minimize maintenance tasks and downtime.

In addition, Innova’s ODEN strapping head replaces traditional wear components with a servo motor and position control system. This technology reduces the number of mechanical parts, minimizes the risk of strap jams, lowers maintenance costs, and significantly extends the equipment’s service life.

The vertical pallet strapping machine is one of the best automatic packaging solutions for ensuring pallet stability, optimizing cycle times, and reducing incidents during the packaging process. At Innova Group, we design and manufacture pallet strapping systems tailored to the specific needs of our customers. Contact us and discover how we can help you achieve maximum efficiency in your end-of-line operations. Our technical team will be happy to assist you!