Types of Pallet Conveyor Systems in an End-of-Line

What types of conveyor systems exist on the market? How can they improve the productivity of a packaging line? In an end-of-line, conveyor systems are responsible for ensuring a constant production flow and guaranteeing a proper connection between upstream and downstream processes.

In this article, we will review the main types of conveyor systems that form part of Innova’s automated end-of-line systems, which are designed and manufactured entirely in-house. These systems are offered either as part of complete packaging lines or as standalone products to customers who require them.

Types of Conveyor Systems

Roller Conveyor

The roller conveyor is the standard system in all industrial environments that handle palletized products.

This type of conveyor stands out for its compact and durable structure, perfect for transporting any type of load, ideal for heavier products, and capable of adapting to existing installations.

Chain Conveyor

The chain conveyor is used for special pallet formats or to connect lines with different widths. It is also the perfect alternative when the pallet orientation does not allow for safe support on rollers.

The roller conveyor performs well when the pallet boards are positioned perpendicular to the direction of travel, as the rollers always provide support. However, when the pallet boards are aligned parallel to the travel direction, the rollers can fall between the pallet slats, causing jams or unstable movement.

With chains, the pallet rests continuously and evenly, ensuring smooth, secure movement without interruptions.

Additionally, this type of conveyor is commonly used in 90° transfer systems, as it allows for connection with roller conveyors.

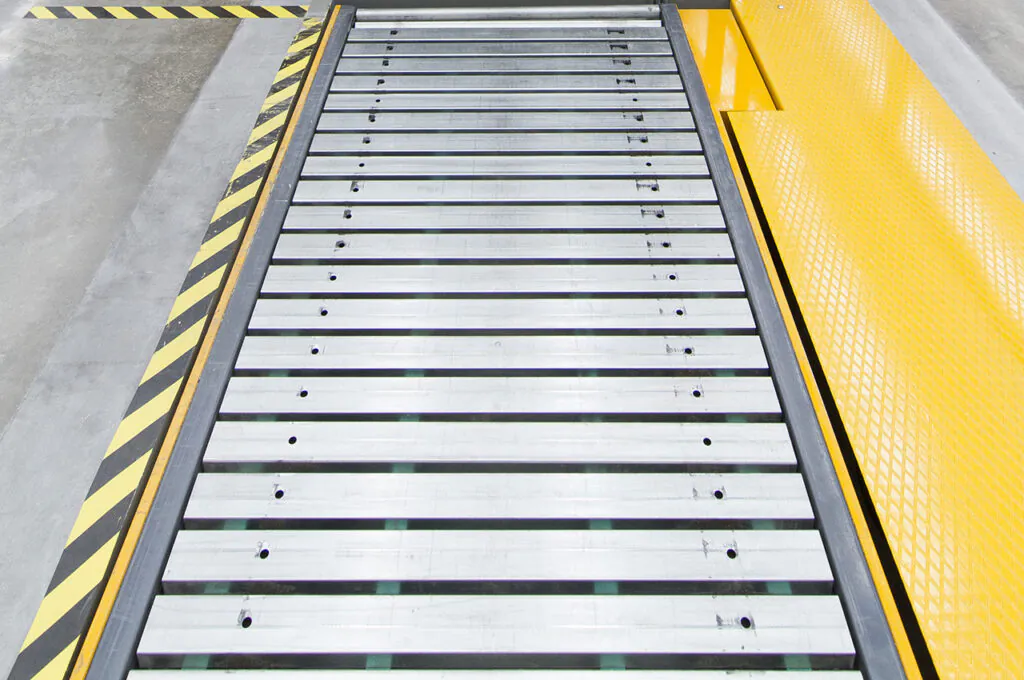

Slat Conveyor

The slat conveyor is designed to integrate into lines that require greater accessibility, such as for manual pallet jacks or forklifts. Unlike rollers, slats cannot support as much weight, making this system more suitable for light or medium loads, typically transported on plastic pallets or smaller formats.

Its open and accessible design makes it the best solution for production plants with frequent manual handling of loads, as this system combines the safety of automated conveying with ease of operator access.

Belt Conveyor

The belt conveyor is commonly used in production or packaging lines, but it can also be integrated into an end-of-line system.

Its main advantage over other systems is its ability to move specific load formats such as palletless sacks, boxes, or big bags that are not placed on pallets. Thanks to its continuous surface, the belt conveyor ensures that these types of loads remain completely stable and secure during transport.

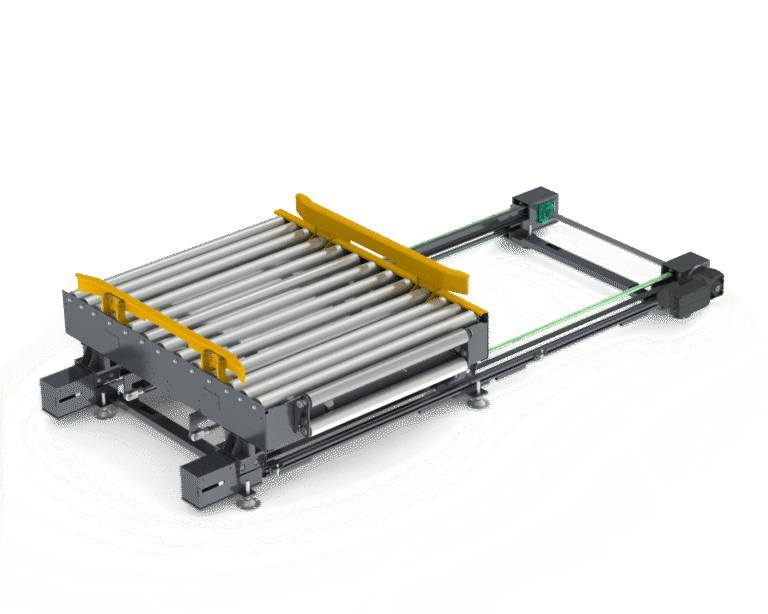

Low-Height Conveyor (Height 100)

The Height 100 conveyor is a roller conveyor designed to integrate at floor level. It is the perfect alternative for packaging lines in facilities that load and unload pallets using manual pallet jacks.

Accessories for Conveyor Systems

- Centering Device: An additional component that ensures the load is centered throughout the entire conveying path. It can detect pallet format upon entry and send information to subsequent packaging systems.

- Aligning Wheels: An alternative to the centering device, aligning wheels are also used to correct the load position.

- Weighing System: A device that weighs the load and automatically sends the data to the company’s ERP or logistics management system, as well as to all connected line systems. It can be installed either before or after the packaging system.

Types of Turning and Lifting Systems

In addition to the main conveyor systems, an end-of-line often requires auxiliary turning and lifting systems that help correct pallet trajectories, overcome height differences, or connect different production flows. At Innova, we develop these modular solutions to easily integrate them into any end-of-line.

Rotating Platform

The rotating platform is a conveyor that allows the pallet to rotate 45° or 90°, depending on line layout requirements. This turning system is especially useful when the plant design requires changes in direction or when the load needs to be strapped on all four sides of the pallet. Its robust design allows the palletized load to rotate safely without compromising stability.

90° Transfer System

The 90° transfer system combines roller and chain conveyors to move pallets laterally. It is a perfect solution for connecting multiple pallet infeed lines without the need for rotating platforms.

Transfer

A guiding mechanism installed beneath the conveyor that enables horizontal pallet movement to connect parallel production lines.

Scissor Lift Platform

The scissor lift platform is a conveyor (either roller or slat) that includes a vertical lifting system. Its function is to adjust the load height to match the packaging line level. It is used to lift the load from floor level for manual pallet jack access or to connect conveyors at different heights.

Pallet Elevator System

The pallet elevator is a vertical conveyor system that moves loads between different production levels. It includes an integrated roller conveyor that ensures stable and secure pallet movement when connecting the upper and lower levels of a packaging line.

As we’ve seen, conveyor systems are essential to ensure a continuous production flow in an end-of-line. They also make it possible to adapt the packaging line to the plant’s layout and design, optimizing available space without compromising productivity or operational efficiency.

At Innova Group, we design and manufacture conveyor systems tailored to the specific needs of our customers. Contact us and discover how we can help you achieve maximum efficiency in your end-of-line. Our technical team will be happy to assist you!