Why Stretch Hood offers the best protection for the Building Materials Sector

Why is the Stretch Hood system one of the preferred packaging solutions for the building materials sector? What advantages does it offer compared to other conventional systems such as stretch wrapping or shrink wrapping? Products such as roof tiles, bricks, concrete blocks, panels, and other heavy goods require extra protection during transportation and storage.

In recent years, Stretch Hood has stood out for its advantages in protection and waterproofing, film savings, load stability, and flawless presentation, as we can confirm from our experience as manufacturers of packaging systems for the construction sector, with hundreds of installations worldwide.

In this article, we analyze the packaging needs of the building materials industry and explain how Stretch Hood can help meet them.

Packaging needs and requirements in the Building Materials Industry

Outdoor storage, shipments traveling thousands of kilometers, damage caused by external factors, unstable loads, multi-format and picking loads, heavy yet fragile products… There are many challenges in this sector and multiple packaging requirements that manufacturers must address when organizing the logistics and storage of their products.

We can summarize some of these needs and requirements common to construction products as follows:

- Protection and safety: Building materials, most of which are heavy and fragile at the same time, require packaging that guarantees their integrity during transportation and storage, avoiding damage and financial losses.

- Adaptable packaging: Many manufacturers handle multi-format loads of various sizes or picking loads that are difficult to standardize under a single solution. This applies, for example, to materials such as blocks, plaster, and similar, or in the case of enamel chemistry with formats in big bags, sacks, and others.

- Logistical requirements: In the global logistics context, companies increasingly need packaging systems that not only ensure load stability but also allow for greater control and traceability to meet the sector’s logistical demands.

- Smart automation and operational cost optimization: The modern automated industry requires connected and faster packaging systems that reduce time and resources, improve production efficiency, and lower operational costs.

- Sustainability requirements: Like other manufacturing industries, the building materials sector must comply with regulations aimed at reducing carbon emissions, plastic use, and energy consumption.

Why Is the Stretch Hood System the preferred packaging option?

There are several packaging systems on the market that provide excellent protection for this type of load. Each system offers its own advantages and characteristics depending on the packaging objective and product type. For example, strapping systems provide superior load securing, while stretch wrapping systems are highly versatile and adaptable, although they may require additional top covers for full protection.

Shrink wrapping is also widely used for its protective qualities, but in recent years, it has increasingly been replaced by Stretch Hood due to its higher speed, productivity, and energy efficiency.

So why do we specifically recommend Stretch Hood? It combines many of the benefits of other solutions, complete sealing and protection, transport safety, and a superior-quality finish.

What advantages does Stretch Hood offer for bricks, blocks, mortar, and more?

As we have seen, this sector has several demanding packaging requirements, all of which Stretch Hood can meet thanks to its unique advantages:

1. Total protection and waterproofing

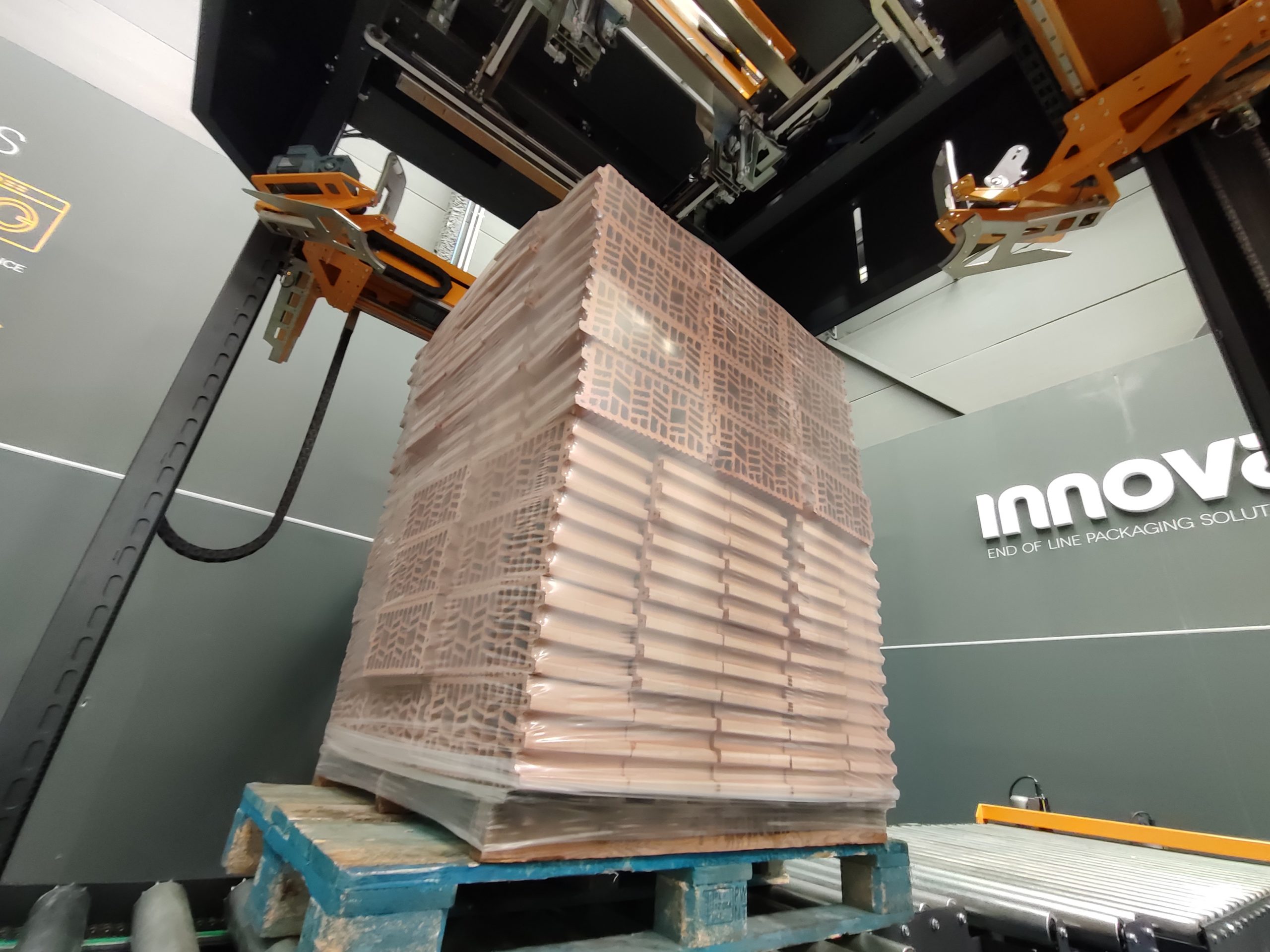

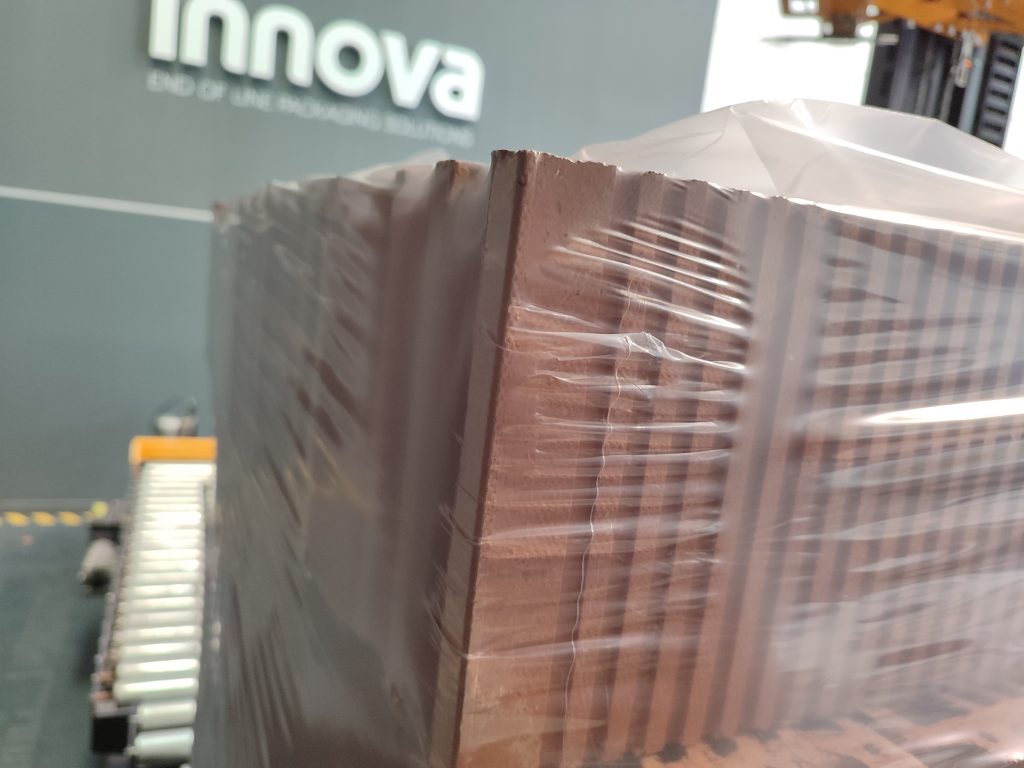

It is the only system that provides total protection and waterproofing. While strapping ensures load stability, it needs a complementary system to offer protection. In stretch wrapping systems, external agents such as rain or dust can seep between film layers. In contrast, the Stretch Hood system completely covers the load with a single tubular film that adapts to its dimensions, protecting the product from external agents and preventing surface damage caused by impacts or abrasions during handling or transport.

2. Speed and autonomy in the Packaging Line

Stretch Hood is one of the fastest packaging systems on the market, capable of wrapping up to 120 pallets per hour, allowing it to meet the high production volumes of the construction industry. Moreover, it offers the greatest autonomy — one Stretch Hood film roll can wrap approximately 800 to 1,000 pallets without the need to stop the machine to change the film.

3. Adaptability to multiple formats

The construction industry works with many load formats — whether roof tiles, concrete blocks, or other finishing and design materials such as marble slabs. Each presents different pallet dimensions and configurations. Stretch Hood stands out for its adaptability, both in the properties of its film and in its ability to wrap everything from small picking loads to large-format pallets. For example, Innova’s Stretch Hood XL system can wrap loads up to 3,800 mm in length.

4. Packaging cost savings

Unlike other systems such as stretch wrappers, Stretch Hood uses a single film sleeve to secure the load. It applies the exact amount of film required to protect any type of construction material, reducing waste and film excess, achieving up to 50% savings in consumables.

5. Brand visibility and presentation

In such a broad sector as building materials, where many products appear similar despite coming from different manufacturers, final packaging becomes a key factor for enhancing brand image. Stretch Hood not only delivers a flawless, wrinkle-free finish, but its transparent film also ensures that logos, labels, and barcodes remain perfectly visible, improving both logistical traceability and perceived product quality. Additionally, the system allows for custom-printed film with the company’s logo, further reinforcing brand identity.

6. The most sustainable packaging system

As mentioned, the construction industry increasingly demands sustainable solutions, and Stretch Hood stands out as the most environmentally friendly system. In addition to reducing plastic use compared to stretch wrapping, the system is equipped with low-consumption drives and motors, and it operates without thermal energy (or gas installations), unlike shrink-wrapping systems. This reduces CO₂ emissions and energy consumption, minimizing the environmental footprint. Furthermore, Stretch Hood allows the use of films with a high percentage of PCR recycled content. All of this makes Stretch Hood the perfect packaging system for meeting the construction industry’s sustainability and efficiency goals.

It’s no coincidence that Stretch Hood has become the solution that best meets the demands of the building materials sector. It combines complete product protection, load stability, cost savings, sustainability, supply chain efficiency, and enhanced brand image. These advantages make Stretch Hood the top choice for the construction industry, where safety and efficiency are of utmost importance.

At Innova Group, we are machinery manufacturers specializing in the ceramics and construction sectors. Since our beginnings, we have developed systems and solutions tailored to the evolving needs of this dynamic industry, which continues to adapt to the demands of an increasingly competitive market. Do not hesitate to contact our specialized technical team, we will help you optimize and improve your end-of-line packaging.