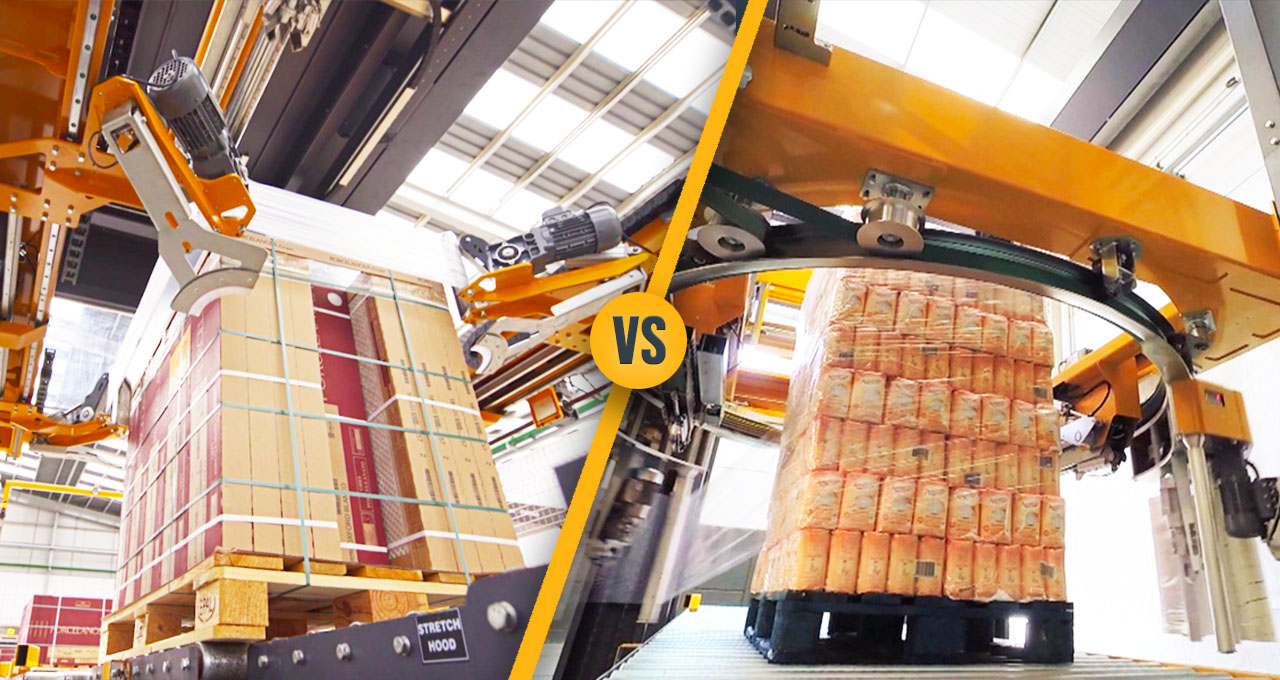

Comparative between packaging systems: Stretch Hood vs. Stretch Wrap

Which is better, pallet Wrapping or Stretch Hood system? Which one provides me more protection? How do I get better load securing in transport? There are many questions and concerns when it comes to choosing a pallet wrapping system, and although their processes are very different, the final result may not be so far apart. Some time ago we compared the hood wrapping systems (Stretch Hood vs. Shrink Hood), now in this article we compare the pallet wrapping machine against the Stretch Hood, explaining the keys and advantages of each one of them.

The packaging process, the great point of differentiation

As their names indicate, the two systems carry out a different process to protect the pallet:

- The automatic pallet stretch wrapper system, the best known and most widely used, wraps or bundles the load with stretch film using several wraps to cover the entire pallet. This system covers and protects the lateral sides of the goods on the pallet, and usually requires the application of a plastic cover on the top side of the load to protect it. The automatic pallet wrapper has the option of applying a reinforcement cord system to provide extra support.

- The Stretch Hood system applies a hood over the load that covers it to the base of the pallet. It uses a tubular Stretch Hood film that is also stretchable to adapt to the shape of the goods. As it has the shape of a hood, it completely covers the 5 visible sides of the product. The Stretch Hood system can also perform different types of stretch hooding to reinforce load securing, such as not covering the top, or reinforcing the hood at the base of the pallet.

Packaging Objectives: Which system is best for what?

According to our experience in many packaging projects, the main objectives are always the securing and protection of the load for handling and storage. However, depending on the type of product and palletizing, more protection will be needed than securing or vice versa.

We usually recommend for each objective:

- Total protection: The Stretch Hood system is the only one that provides total protection and impermeability, as it does not allow dust, humidity or water to get through, as it could happen between the wrapping and cover layers. In addition, the film itself contains properties against UV rays to protect the load even from the sun.

- Total hold: The industrial pallet wrapper is best known and noted for its grip, since it can apply different tensions during wrapping as well as the reinforcing cord, which acts as a strapping band. However, the Stretch Hood System can also offer hold using a specialized type of reinforcement hooding at the base or body of the load.

Are these packaging systems substitutes or complements?

At this point, the most common question is: are these systems substitutes or do they complement each other? In principle, both serve the same purpose of protecting and securing the load, so in many cases they are fully substitutable. However, sometimes the stretch wrapping equipment can be used as a complementary system to the Stretch Hood and vice versa, as each can fulfill a different function.

Depending on the type of industry and product, one or both systems can be used to reinforce the hold. Some examples:

- Ceramic pallets: They need a lot of support as the product is heavy but delicate, as well as total protection due to outdoor storage and transportation. Therefore, the wrapping machine can be used for securing (instead of strapping) but the Stretch Hood system will be necessary for total ceramic protection.

- Pallets of cement or chemical bags: Their actual palletizing gives them stability, so this industry is progressively changing the Stretch Wrapping for Stretch Hood to gain more protection and impermeability for their product.

- Miscellaneous food pallets: In many occasions these are light pallets (compared to cement or ceramic) and they need a greater hold to wrap their uneven load. This is why it is more common the use of the pallet wrapper for food.

Let’s see below the generic advantages offered by each system in the context of an automatic packaging line.

Comparative 1: Advantages of Stretch Hood Vs. Stretch Wrapping Machine

In addition to the aforementioned objectives of protection and support, we describe other advantages of the hooding system:

- Faster wrapping speed

The stretch hood application system is usually faster than a standard stretch wrapper cycle, as the Stretch Hood can pack between 100-130 pallets/hour, while a conventional automatic wrapping machine would do between 60-80 pallets/hour (check also our semi-automatic wrapping machine). In the production line, while the Stretch Hood is wrapping one pallet, the next pallet’s hood is already being prepared, thus allowing continuous production.

- Increased Productivity

With an average usage calculation, a single Stretch Hood film reel can stretch wrap 800 to 1200 pallets; whereas a conventional stretch film reel can only wrap around 150 pallets by using a larger amount of film. This means that the Stretch Hood reel only needs to be changed in 5 to 8 working hours, while the stretch wrapper reel is usually changed in just 3-4 hours. In short, the Stretch Hood allows fewer stops for reel changes and increases productivity.

- Saving on consumables

Stretch Hood also saves on film usage as it only uses the film that is strictly necessary to cover the load. Meanwhile, the pallet stretch wrapping system requires the use of more film and even the application of a protective cover.

- Protection against external agents

As mentioned above, the properties of Stretch Hood film provide total sealing and protection of the load against external agents such as dust, UV rays and even rain. The process of hooding also helps to seal the load as it covers the load all the way to the base of the pallet.

- Transparency and visibility

The Stretch Hood provides total transparency, increasing brand and product visibility, as well as legibility and label protection inside the film. It also offers a higher quality finish, as there are no layers, wrinkles or protruding plastic residues typical of stretch wrapping.

Comparison 2: Advantages of the Stretch Hood Wrapper over the Stretch Hood

- Greater hold

As we have seen, the pallet stretch wrapper is the system of choice for securing. Its wrap-around effect and the application of the securing cord provide a better hold, even with light or unstable loads. However, it is closely followed by Stretch Hood, which in recent years has been developed to provide specialized securing wrapping.

- Adaptability

Another advantage of the traditional pallet wrapping machine is its adaptability to different types of loads, since the wrapping can be adapted to the shape, with different types of film tension and cord reinforcement. It also allows to use more or less pressure depending on the delicacy of the product.

- Optimization of film usage

On high-end automatic stretch wrappers, film can be optimized to the maximum thanks to the pre-stretch system and the torque control systems. Depending on the industrial wrapping cycle, it is possible to use the same amount of film or even less than with the Stretch Hood system.

- Wide range of pallet wrapping systems

Being such an extensive packaging system, another of its advantages is that there is a wide range in the market, from semi-automatic pallet wrappers, robot wrappers, rotating arm wrappers, automatic ring wrappers, etc. Depending on the production needs and capacity of each customer there are several options, which is not so much the case with the Stretch Hood, which is only used in automated production.

In summary, as we have seen, both systems have advantages in their favor and above all different applications depending on the product and purpose required. Also both systems are evolving rapidly in recent years, and although the Stretch Hood system is more innovative, automatic stretch wrappers are not far behind in terms of speed and film optimization.

Don’t hesitate to consult with our technical team to find out which system can provide you the greatest benefits for your product and your company. Your project is in the best hands of our experts!

#WeAreInnovaTech

#WeAreInnova