Innova Packaging Solutions to Showcase Stretch Hood’s Advantages at Pack Expo International 2024

Are you looking to reduce losses and damages during product transport? Seeking higher-quality packaging while saving on consumables? At Pack Expo International 2024, Innova will present its advanced Stretch Hood technology, designed to ensure maximum product protection, impermeability, and cost savings on consumables and energy.

Why Stretch Hood is the Preferred Wrapping System for Modern Industries

Stretch Hood is among the most innovative and adaptable pallet packaging technologies available today. Known for its versatility, Stretch Hood can accommodate a wide variety of product types, industries, and formats. With its ability to replace traditional stretch wrapping in numerous applications, this system has become an essential choice for industries seeking advanced automation solutions. But what exactly makes Stretch Hood so adaptable for diverse loads?

The answer lies in its unique ability to provide customized packaging for each load, ensuring a secure, efficient wrap every time.

Stretch Hood: Versatile Applications for Diverse Industries

Stretch Hood is utilized across multiple industries for end-of-line packaging, offering solutions for various load types:

- Palletized Goods Transport: Whether products are in primary or secondary packaging, Stretch Hood ensures they remain securely wrapped for safe transport and storage.

- Palletless Transport: Ideal for formats like household appliances or other products designed for transport without a pallet, such as bagged goods.

- Small Formats: When traditional stretch wrapping isn’t feasible, such as with smaller product sizes requiring protection, Stretch Hood offers an effective alternative.

Hooding Vs Wrapping: The Key to Achieving a Superior Finish

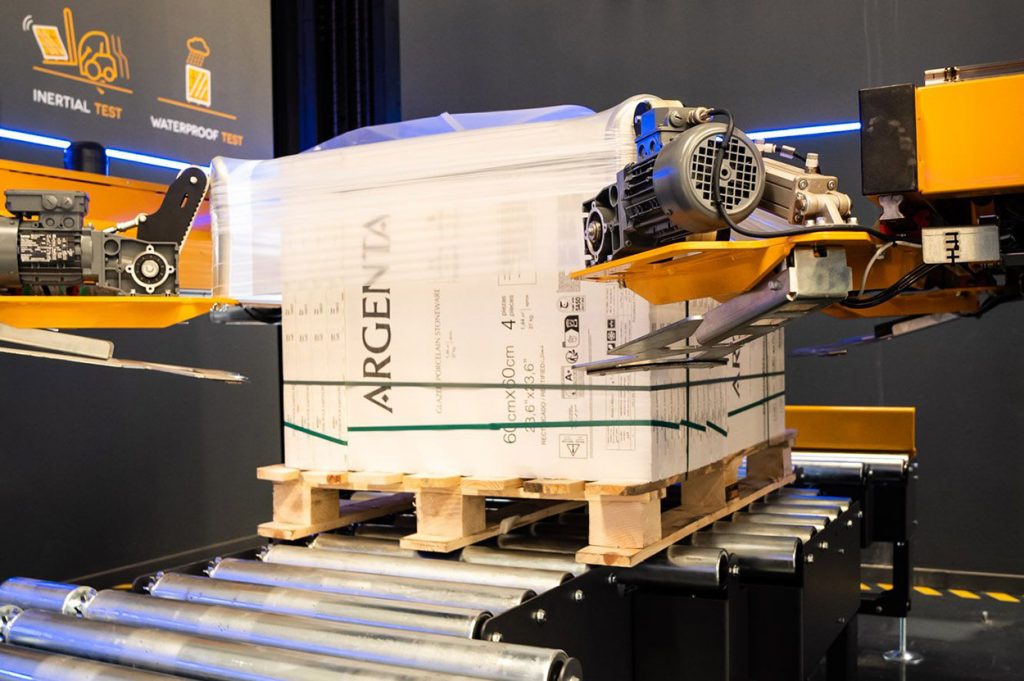

The Stretch Hood system incorporates cutting-edge features that set it apart from other wrapping technologies. These innovations include the unique hooding process, adaptable machine design, and advanced components, such as intelligent sensors and energy-efficient motors. Additionally, Stretch Hood’s tubular film is specifically engineered to match each load’s dimensions precisely, allowing for a snug, protective fit.

A standout feature of the Stretch Hood system is its custom-designed film. Unlike the stretch film used in traditional wrapping machines, the Stretch Hood film is a multilayer LLPDE polymer with exceptional waterproofing and stretching capabilities. This film enhances load protection and provides outstanding clarity, making it ideal for product presentation and branding.

Experience the Stretch Hood Advantage Live at Pack Expo

Attendees of Pack Expo 2024 will have the unique opportunity to witness live demonstrations of the Stretch Hood system at Innova’s booth. Through real-time tests at the Innova Lab Test Area, visitors can see firsthand how Stretch Hood delivers secure, adaptable, and high-quality packaging for various applications. Our team will be on hand to answer questions and discuss how this technology can be tailored to meet specific product protection needs.

Discover at Pack Expo How Stretch Hood Can Benefit Your Products

Join Innova End Of Line Packaging Solutions at Pack Expo International in Chicago to explore our state-of-the-art packaging technologies. Discover how Stretch Hood can enhance your product protection, reduce logistics issues, and optimize packaging costs.