Packaging Solutions for Drums: Safety, Stability, and Efficiency in Every Load

What are the primary packaging challenges for drum loads? What solutions provide better protection and support? Which system is the most efficient? Drums are an essential container for storing and transporting liquids and chemicals. However, their cylindrical shape, weight, and the nature of their contents pose significant technical and logistical challenges at the end of the line. Ensuring their stability during transport, preventing spills or leaks, protecting the product from environmental conditions, and complying with international safety regulations are key aspects that require specific packaging solutions.

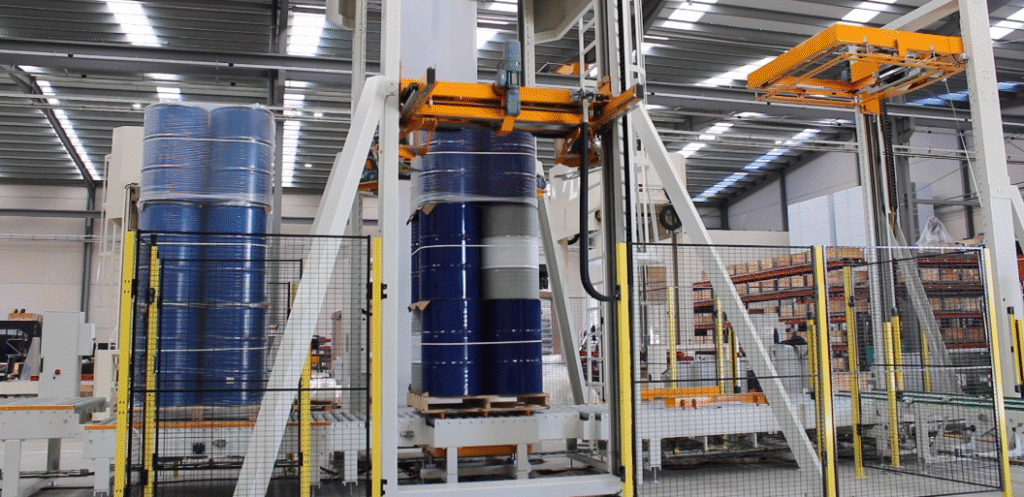

At Innova Group, we design packaging systems tailored to these specific requirements, guaranteeing maximum support, protection, and stability for this type of load. Throughout this process, we have optimized line efficiency and reduced risks throughout the logistics chain.

Challenges of Drum Packaging

Drum packaging has different characteristics that set it apart from other types of palletized loads:

- High weight per unit: A standard 200-liter drum when full weighs over 200 kg, a very heavy load that requires robust securing to prevent movement during transport.

- Instability in stacked loads: When drums are empty and stacked at various heights to optimize space, the load acquires a higher center of gravity, increasing its instability and therefore the risk of tipping if not secured correctly.

- Cylindrical and smooth surface: Unlike other types of loads, such as boxes or bags, drums do not fit together as they are cylindrical and have a completely smooth surface, which makes compaction and stability difficult.

- Risk of leaks and safety regulations: The transport of drums containing liquids, especially chemicals, is subject to various international regulations such as the ADR Agreement. Inadequate packaging not only compromises product safety, but can also cause environmental damage and legal penalties.

Innova packaging solutions

At Innova Group, we adapt to the specific needs of each drum load, whether it is a homogeneous load or a combination of different sizes. These are the most effective solutions:

1. Vertical strapping: Direct attachment to the pallet

Vertical strapping is a perfect system for securing drum loads directly to the pallet. It applies straps from the top to the base, ensuring that the load does not move. In full drums, vertical strapping immobilizes the load on the pallet, preventing the weight from causing lateral movement. In stacked loads, it can also be used to secure several levels of height to each other.

2. Horizontal strapping: Compaction by levels

Horizontal strapping is ideal for stabilizing palletized drum loads, as it firmly binds the drums together along each level, preventing them from shifting sideways (radial movement) during transport or handling.

This system is particularly useful when working with empty drums stacked at great heights, a configuration that tends to be unstable. By applying straps at different heights, compact “blocks” are created, where each row of drums is secured as a solid unit, improving the overall stability of the load.

3. Wrapping machines: Maximum stability and hold

Wrap machines, whether ring or rotary arm, apply stretch film around the entire load, binding the drums together and forming a compact block. In addition to providing stability, the film protects against external agents such as dust and moisture.

For low-height loads with full drums, wrappers are the perfect solution, as the tension of the film holds the heavy drums together, preventing any movement during transport. For taller loads with empty drums, the wrapping machine can also be used, but due to their instability, it is advisable to combine it with horizontal strapping. This secures each level of drums before bundling, preventing them from moving during the packaging cycle.

4. Stretch Hood: Efficiency and total protection

The Stretch Hood system optimizes film consumption thanks to its different wrapping programs. In the case of drum loads where the base or top needs to be reinforced, Stretch Hood applies only the amount of film necessary in those critical areas, avoiding unnecessary use of consumables around the entire load.

In addition to its efficiency, it provides total protection and impermeability, as it completely covers the drums and insulates them from external agents such as dust, rain, or UV rays, even during prolonged outdoor storage.

Stretch Hood also provides drum loads with a firm and stable hold thanks to the combination of vertical and horizontal shrinkage, which secures the drums to each other and the pallet. When full, it prevents movement due to weight; when empty and stacked, it maintains verticality and reduces the risk of tipping during handling.

In short, drum packaging requires systems specifically designed to meet the challenges of weight, shape, and instability, combining support, protection, and efficiency. At Innova Group, we design, manufacture, and install systems adapted to the complexity of this type of load, ensuring that each drum arrives in perfect condition, optimizing resources and line performance.

If you work with this type of load, at Innova we will be delighted to help you. Contact our technical-commercial team, and we will work with you to find the best solution for your production line.