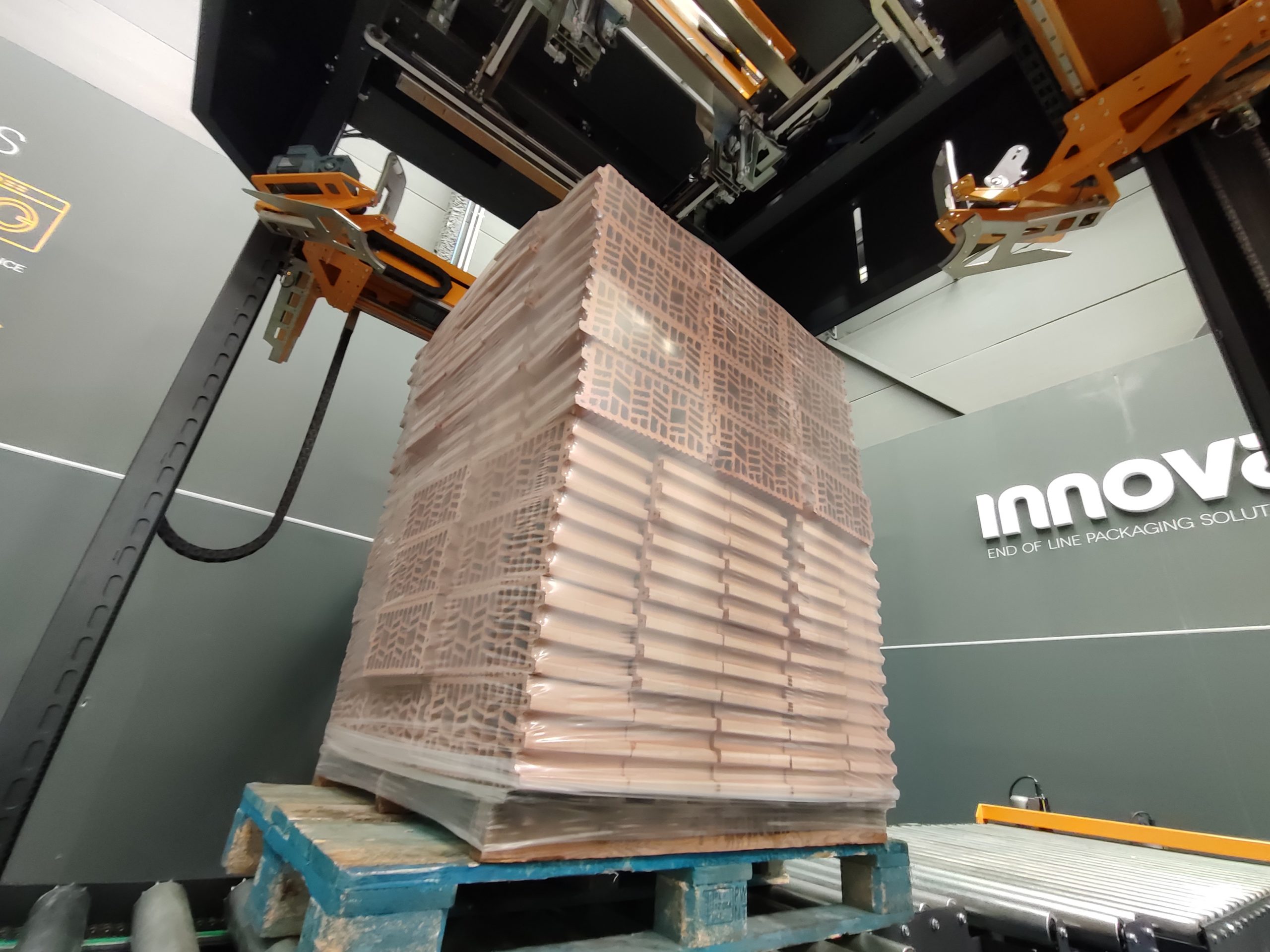

The Stretch Hood wrapping system developed by Innova ensures the highest protection for construction material loads. The tubular wrapping and film characteristics provide watertightness and protection against external agents. This system provides full load coverage, ensures transport safety, and delivers a superior quality finish that adds value. Stretch Hood is the most environmentally sustainable option, reducing consumables and energy costs by up to 50% compared to automatic wrapping or heat-shrink wrapping solutions.

Developed and manufactured by Innova, ur Strapping Systems offer the ultimate fastening solution for construction material pallets. The horizontal strapping system guarantees optimal load compaction, while the vertical strapping system ensures unmatched stability and complete fastening to the pallet base for secure transport, including the option for cardboard edge protectors to provide maximum protection for tiles and bricks.

Our strapping systems allow for the position and number of straps to be adjusted to accommodate different pallet sizes.

Get maximum stability and support for transporting building materials with Innova stretch wrappers. The Ring Stretch Wrapping and the Arm Stretch Wrapping include a roping device, which offers an extra fixation on the load similar to the strapping application. In addition, they also include a cover applicator accessory and cardboard edge protectors applicator to provide even more protection for the load.

Ensure absolute protection and airtightness for your load with this powerful system. It features an automatic pallet hooding machine and a thermo-shrink system that meticulously applies and shrinks the film at 280ºC. The Shrink-hood system perfectly conforms to the pallet’s shape, utilizing heat to secure the film and protect the pallet from external elements. Furthermore, it effortlessly accommodates various pallet sizes using 3 reels to configure different dimensions.

Automatic strapping systems offer the best hold and support for heavy loads. Our robust strapping systems guarantee enhanced speed and safety, thanks to their durable design. Moreover, the edge protector applicator ensures that the product is shielded from strapping tension and is optimized for efficient transport.

Other recommended systems for securing materials include the use of ring or arm stretch wrapping automatic machines. These stretch wrapper allow the material block to be held and compacted using a roping device.

Stretch Hood technology is widely recognized and used in the industry for protecting cargo from external elements such as dust, sun, humidity, and rain during outdoor storage. This system ensures a completely airtight hood while using less film compared to the heat shrink method. With Stretch Hood, a single film layer stretches and conforms to the shape of the load, eliminating the need for heat application.

The heat shrink system is also an option for total protection and airtightness, but in recent years it has been superseded by Stretch Hood.

One important goal for the building materials sector is to streamline their logistics by using more compact and easier-to-handle loads. To achieve this, the best packaging systems are the automatic strapping system, which secures the load with strapping, and the Stretch Hood, which uses a hood film to protect the product. The Stretch Hood also offers transparency for clear visibility and traceability of logistics codes.

Packaging is the presentation of your company, and a quality finish adds value to the delivery of the product. In this case, both Stretch Hood and the heat shrink system offer transparency for brand visibility, and in both systems you can print your logo on the films.

In particular, the Stretch Hood uses films with a lower thickness compared to the Shrink Hood, resulting in a crease and wrinkle-free presentation.

The building materials sector must comply with several key regulations related to logistics and transport as directed by the FMCSA in the US, or by the EU in European countries. To meet the requirements in terms of load safety, we recommend using securing systems such as strapping or stretch wrapping machines.

The industry is demanding more sustainable solutions, and Stretch Hood stands out as the most efficient and environmentally friendly packaging system. In addition to reducing the use of plastic, it reduces CO2 emissions with highly efficient motors for a lower energy consumption.

Join the #SustainableThinking!