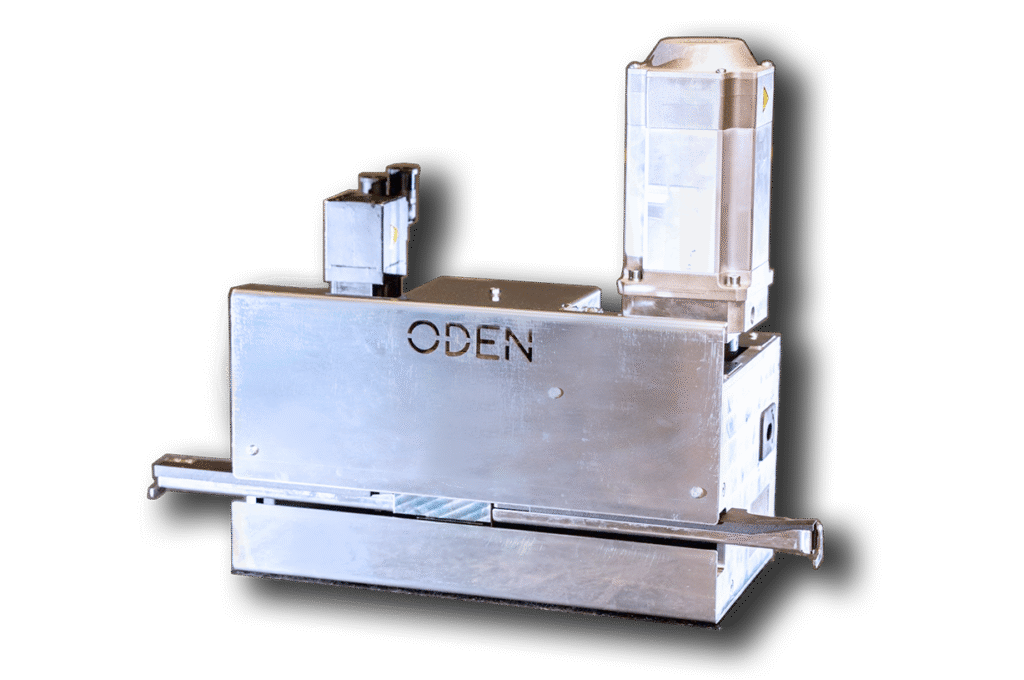

STRAPPING HEAD 'ODEN SMARTDRIVE'

Universal integration head with other strapping equipment

Discover the ODEN SMARTDRIVE Strapping head, developed and patented by Innova Group. ODEN is among the most advanced strapping heads on the market, featuring a lightweight, compact design and connectivity technology that enables installation not only on Innova strapping systems but also on equipment from other brands.

ODEN SMARTDRIVE delivers greater performance and precision in strapping, thanks to its advanced electronics and torque-control technology for tension adjustment. It includes fewer mechanical components, is sensorless, and requires less maintenance.

Discover the intelligent Strapping head ODEN SMARTDRIVE

Easy integration with other strapping systems

The ODEN Strapping Head, featuring patented Innova technology, offers easy adaptation and integration with other strapping equipment outside the Innova range, and compatibility with different PLC systems.

Integration is achieved using a Starter Kit consisting of the head and its connection drivers. Various optional elements are available depending on customer requirements, such as a touchscreen HMI, a strap frame, a strap unwinder, and/or a strapping verification system.

Web display and remote management

The head includes web access to the control and configuration interface. This allows remote access to:

- General cycle settings

- Editing and viewing strapping recipes

- Manual control of the head

- Viewing the position of the strapping cycle

- Diagnostics, viewing warnings and alarms for the head

- Counters/production history for strapping

- Counters/history for consumables

Less wear and tear for better maintenance

The ODEN head is sensorless and designed without wear components such as clutches and brakes. It also has fewer pulleys, reducing the risk of belt jams.

Its compact design facilitates easy replacement of components, resulting in lower maintenance costs. In fact, maintenance is 30% cheaper due to fewer parts being replaced and reduced wear and tear on them.

Lightweight and compact design

ODEN is one of the lightest and most compact heads, weighing only 50 kg, and with reduced dimensions and footprint. Thanks to its aluminum chassis and the reduction in the number of mechanical components, it is 33% lighter and 46% smaller than heads with similar performance.

Its lightweight design improves the machine’s energy efficiency for applications that require lifting the strapping system.

Strapping speed and precision

The head incorporates a servomotor with positioning control for strapping application, control, and tension. Its torque control technology allows for faster and more accurate maneuvering, reducing cycle times and increasing packaging line productivity.

In the event of a collision during launch, the strap can retract and repeat the maneuver thanks to its intelligent strap arrival detection system. It also allows for controlled stops to strap closer to or further away from the load.

Technical Datasheet ODEN SMARTDRIVE Strapping Head

| Strap welding: | Electrical resistance welding |

| Operating strap dimensions: | 9 -12 -16 mm / 3/8", 1/2", 5/8" |

| Strap thickness: | 0.55 -0.75 mm / 0.022” – 0.030” |

| Strap material: | Polyester (PET) or Polypropylene (PP) |

| Maximum strapping tension: | Up to 2050 N |

| Strapping tension adjustment: | By servomotor with torque control |

| Head dimensions: | 640 x 478 x 239 mm / 25.2 × 18.8 × 9.4 in |

| Head Weight: | 50 kg / 110 Lbs |