Grupo Celima Trebol from Peru chooses Innova Group’s logistics solutions for its end-of-line

In a competitive market such as the high-quality ceramic products manufacturing sector, efficient logistics processes are crucial. Recently, Grupo Celima Trébol, a leading company in the Peruvian and Latin American ceramic industry, has made a significant advancement by optimizing its end-of-line operations with the assistance of packaging solutions provided by Innova Group. They have relied on Innova Group’s expertise to fabricate and install a pallet transportation line and logistical connection at their main Celima factory in Punta Hermosa, Cañete province, in the Lima department of Peru.

Celima (Cerámica Lima), part of the Celima Trebol Group, is a Peruvian company with over 60 years of experience in the manufacturing and commercialization of high-quality ceramic products. It stands out for offering a wide range of ceramic coverings, porcelain tiles, sanitary ware, and faucets for various sectors, from construction to interior design.

Committed to quality and innovation, Celima uses advanced technology and strict international production and packaging standards. The company has a strong presence in Peru and exports its products to several South American countries. In this context, Innova contributes advanced packaging technology and solutions, along with its experience and specialization, having completed hundreds of installations for the ceramic sector.

Celima’s Logistic Challenge

Celima’s challenge was clear: To efficiently connect its end of line, composed of two packaging systems, through a logistical solution that would ensure the integrity of the products and streamline the transportation process of the already packaged pallets. They also faced the particular challenge of the location and space of their factory, needing a solution fully adapted to these requirements. For this reason, they chose Innova Group due to their experience in designing and manufacturing conveyor connections and logistical solutions for ceramics.

Logistic Conveyor Line Project

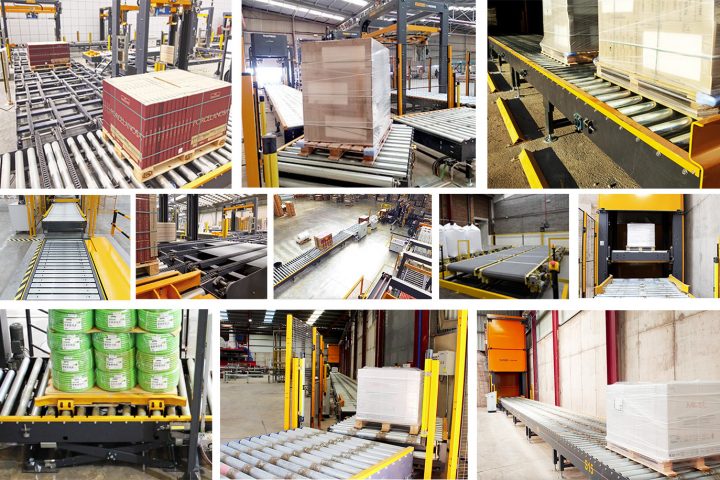

To address this challenge, Innova Group designed a custom line that perfectly adapted to Celima’s facility. Innova manufactured and installed a conveyor line comprising 28 roller conveyors and 4 pallet turners, spanning a total length of 76 meters. This transport line was seamlessly integrated with the current packaging systems, serving as an exit station for the already packaged pallets towards the collection and logistical processing station.

Innova’s type of roller conveyor ensures the safe movement of pallets, minimizing the risk of damage during the long journey that Celima needs to undertake. Innova specializes in the design and manufacture of this type of special conveyor for ceramic loads, with robust and secure systems to support the heavy weight of tile and porcelain products.

The coordination between the teams from Celima and Innova Group was essential to ensure a seamless installation and perfect integration with the existing systems. Tests were conducted to verify the conveying line’s performance and ensure its capacity to handle Celima’s production flow efficiently.

Project Results

The solution implemented by Innova Group brings numerous benefits to Celima, allowing for greater efficiency at the end of the line, reducing waiting times, and increasing the availability of loads for logistical processing and storage.. The smooth connection between the packaging and conveyor systems has minimized bottlenecks and improved the overall productivity of the plant.

The collaboration between Celima Trébol and Innova Group has resulted in a significant improvement in Celima’s logistics processes and increased competitiveness in the Peruvian ceramic market. This project exemplifies the value of technological innovation in the Latin American ceramic industry.

From Celima’s side, they have expressed their satisfaction with the project: “Innova Group’s custom solution has been fundamental in improving our logistics processes and has allowed us to increase efficiency at our end of the line. Their knowledge of the ceramic sector and ability to offer customized solutions have been key to the success of this project.”

From Innova’s side: “We are proud to work with a leader in the Latin American sector like the Grupo Celima Trébol. Projects like this consolidate our commitment to innovation and automation in the Peruvian and Latin American industry.” This project exemplifies effective collaboration between two companies and demonstrates the positive impact of automatic packaging solutions on optimizing industrial processes.

Thank you, Celima, for choosing Innova!