How to choose the pallet packaging system according to the load protection objectives

In an evolving socio-economic context, the industrial sector must respond to increasing demands and requirements in logistics and transportation. In this regard, end-of-line automation, and in particular pallet packaging systems, play a key role in meeting these international logistics requirements and improving the safety of goods. Choosing the optimal packaging system, according to the company’s objectives and the logistical context, is becoming more than a necessity for companies wishing to compete in this dynamic economic environment.

In today’s article, we will explore the importance of defining objectives in packaging projects, and how to select the most appropriate systems according to those objectives, based on our experience as packaging machinery manufacturers and a multitude of installations around the world.

Why is it important to define objectives in a packaging project?

Before selecting the pallet packaging system, it is essential to establish the desired goals to be met. In addition to the load’s requirements, the technical or logistic manager must take into account compliance with regulations, customer requirements, supply chain demands, transportation methods used, etc.

Some of the most sought-after objectives are:

- Greater stability in transport, especially for fragile and heavy loads.

- Protection of the cargo against external agents, such as dust or rain (either in storage or transport).

- Faster packaging process to respond to high production or growth forecasts.

- Sustainability and reduction of film use, due to our sustainable standards and objectives.

- Customized packaging finishes, according to customer requirements or regulations.

System recommendations according to packaging purpose

Tell me what your objective is and I will tell you what packaging system you need… Although some pallet packaging systems are more versatile than others (as is the case of Stretch Hood), it is clear that there are systems or combinations of these that are advisable if we are looking for a specific objective such as maximum securing, for example, or total protection.

Protection against external agents: Stretch Hood System

For maximum protection of the cargo against external agents, such as dust, humidity, and even rain, the Stretch Hood system is the preferred option. This system covers the entire load with a high-strength stretch film, sealing it against moisture and damage caused by adverse weather conditions, such as snow and even hail. It does not allow even a drop to seep through, unlike the pallet wrapping system, which can leak between layers of film.

Increased transport stability: Strapping and/or Wrapping systems

For greater load stability during transport, especially in the case of fragile or very heavy loads, two systems are recommended to prevent shifting:

- Strapping systems: Vertical strapping firmly secures the load to the pallet, preventing movement and slippage during transport, while horizontal strapping serves to compact the load into a block, offering greater stability for heavy loads.

- Stretch wrapping systems: By using the pallet stretch wrapper specifically with the application of roping device, optimal load securing is achieved, since it allows the load to be secured and fastened to each other and also to the pallet base. If the roping cannot be applied (due to the characteristics of the product, or the performance of the stretch wrapper itself), a wrapping cycle with a higher holding force can be configured to provide that additional hold.

Load securing to the base: Vertical strapping

In cases where the load needs to be more securely fastened to its pallet base, for cargo handling purposes, vertical strapping is recommended. This strapping method binds the load directly to the pallet, preventing it from shifting in any direction during transport.

Another system could be the use of an automatic wrapper with a set cycle to reinforce the lower part of the wrapping, contributing to the union of the load with its base.

Increased speed and high production: Stretch Hood System

For greater speed in the final packaging, we again highlight the Stretch Hood system. By protecting the load with a single layer of film, versus the stretch wrapping machine, this system speeds up the packaging process and guarantees effective protection. The latest models of Stretch Hood systems on the market, increase packaging speed even more, with productions of more than 150 pallets/hour in standard stretch hooding.

Sustainability and plastic reduction: Stretch Hood System

For a more sustainable packaging process that reduces the use of plastic, the most recommended option is the Stretch Hood system. This system reduces the amount of film required by up to 50% compared to the pallet stretch wrapper, resulting in a more efficient and environmentally friendly option.

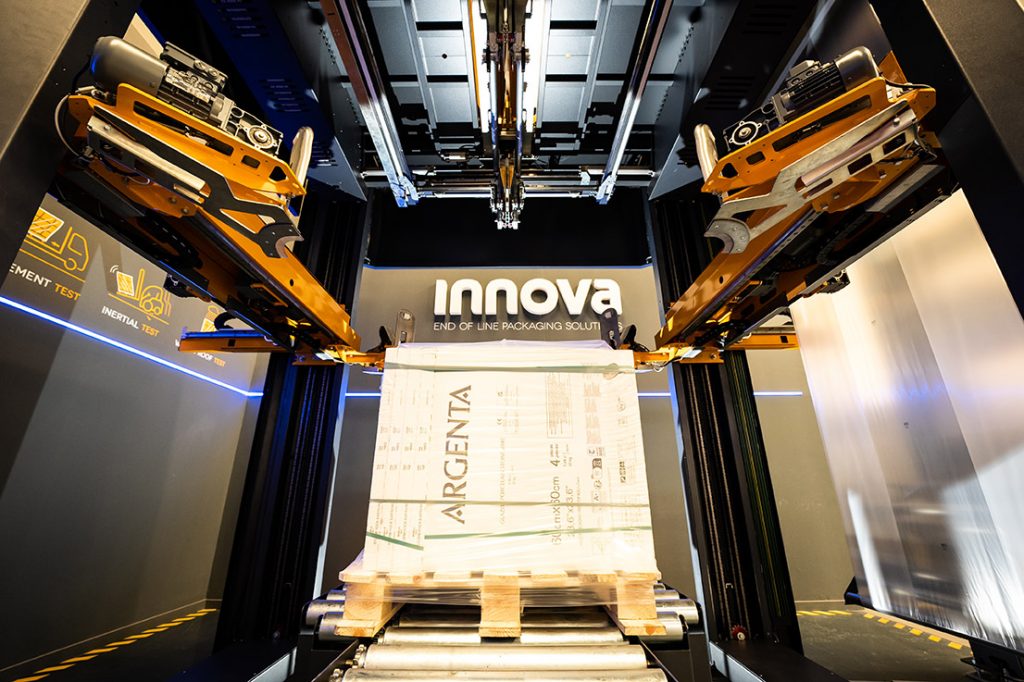

In addition, the film manufacturing industry is currently in the process of R&D developing to produce Stretch Hood films with higher recycled contents, usually around 30% and 50% PCR, while preserving the stretchability and resistance that define this specialized film. In the case of Innova’s Stretch Hood System, we have already certified and tested this type of 50% PCR film to offer a more environmentally friendly alternative to our customers.

Finish customization and branding: Stretch hood system

The Stretch Hood system is once again recommended for specialized finishes, superior load presentation, and branding objectives. Many of our customers consider this as one of the essential requirements when planning a change of packaging system. With the rise of e-commerce and point-of-sale cargo display, as in the case of department stores and retail outlets, the display of palletized cargo is also part of the company’s corporate image.

In this case, Stretch Hood is again the favorite because its hooding covers the load with a single layer of completely transparent film, without creases, wrinkles, or excess film residue as in the case of stretch wrapping. The film is also much more customizable than stretch wrap films, enabling not only custom color but also logo imprinting. With Stretch Hood, companies can highlight their brand and convey an image of professionalism, quality, and added value in each shipment of goods. This translates into a positive impact on the perception and loyalty of the end customer.

In conclusion, there are many factors to consider when choosing the pallet packaging system best suited to your cargo and logistics security objectives. Each company and type of product has unique requirements, so it is critical to be clear on objectives such as those seen in this article before investing in an automated packaging system.

Our advice is always to consult and review with an expert in packaging systems all the casuistry, technical and regulatory requirements, and ultimately the company’s objectives. At Innova, as a specialized manufacturer with hundreds of installations around the globe, we offer free consulting for your packaging project. Our team of professionals will guide you in the selection of the most suitable system for your specific needs. Do not hesitate to contact us!

Do you like our technical posts on packaging and logistics?

Subscribe to our monthly newsletter, no commercial spam, just interesting articles. 😉

SUBSCRIBE: