Improve Your End-of-Line KPIs with the Stretch Hood Packaging System

In today’s industrial environment, where operational efficiency and resource optimization are key factors, measuring logistics process performance is essential. In this regard, the end of the line directly influences plant productivity, costs, and sustainability, and Stretch Hood has become one of the key systems for improving multiple Key Performance Indicators (KPIs).

In this article, we analyze the main KPIs that are improved with the installation of Stretch Hood, and how these improvements can be measured in a packaging line.

1. Cost of Packaging Consumables

Film consumption is one of the most relevant KPIs in any packaging line, as it directly impacts operating costs.

How to measure it in practice:

- Weighing film rolls: Record the roll weight at the start and end of the packaging cycle. This calculation provides grams of film per pallet, a direct and comparable indicator with other solutions. In high-volume production facilities, it can also be calculated based on the number of pallets wrapped per roll used.

KPI Indicator: Grams of consumable or euros per pallet.

Result: A Stretch Hood system can reduce film per pallet by up to 50%. On standard loads, it uses a single tubular film, while on special loads, it applies reinforcement only in critical areas (base or top). This way, load protection is ensured without using more material than necessary.

2. Load Protection and Safety

One of the key indicators for evaluating packaging efficiency is the number of incidents occurring during transport and storage in relation to protection and stability. Each damaged pallet means additional costs due to returns, product deterioration, and a negative impact on the company’s reputation.

How to measure this KPI in practice:

- Logistics incidents: Track damages, claims, or returns in relation to the total number of pallets delivered.

- Technical tests: Perform tilt or handling tests periodically on random samples to verify packaging resistance.

KPI Indicator: Percentage of pallets delivered without incidents.

Result: In plants that have incorporated Stretch Hood, the percentage of pallets with incidents is significantly lower. The outcome is not only cost reduction but also greater customer confidence in the reliability of each delivery.

3. Packaging Line Productivity

End-of-line productivity is a decisive KPI. The ability to wrap more pallets in less time impacts not only plant efficiency but also responsiveness to demand peaks and the reduction of logistical bottlenecks.

How to measure this KPI in practice:

- Pallets per hour: Divide the total number of wrapped pallets by the effective production time (excluding stops or maintenance).

- System comparison: Analyze the plant’s real productivity before and after the installation of Stretch Hood.

KPI Indicator: Number of pallets per hour.

Result: An automatic wrapper-equipped line can reach about 75 pallets/hour, while Stretch Hood can achieve up to 120 pallets/hour. The result of incorporating Stretch Hood at the end of the line is an increase of up to 60% in production capacity.

4. Carbon Footprint Calculation and Energy Efficiency

Sustainability has become a strategic KPI for any company. Stretch Hood helps reduce the carbon footprint of end-of-line packaging by combining energy efficiency, lower consumable use, and emission reduction.

How to measure it in practice:

- Energy consumption per pallet: Record energy used (kWh) divided by the number of wrapped pallets.

- Film consumption per pallet: Track in grams or euros per pallet and compare with previous systems.

- Emissions avoided: Calculate CO₂ reduction compared to shrink oven systems.

- Use of sustainable consumables: Percentage of recyclable or recycled consumables used out of the total.

KPI Indicators: Energy per pallet, grams of film per pallet, avoided CO₂ emissions, and percentage of sustainable consumables.

Result: Sustainability becomes a tangible and measurable KPI thanks to the installation of Stretch Hood. The result is always positive, since it is the most environmentally friendly system by reducing plastic use, employing films with recycled content, and operating with high-efficiency motors and components.

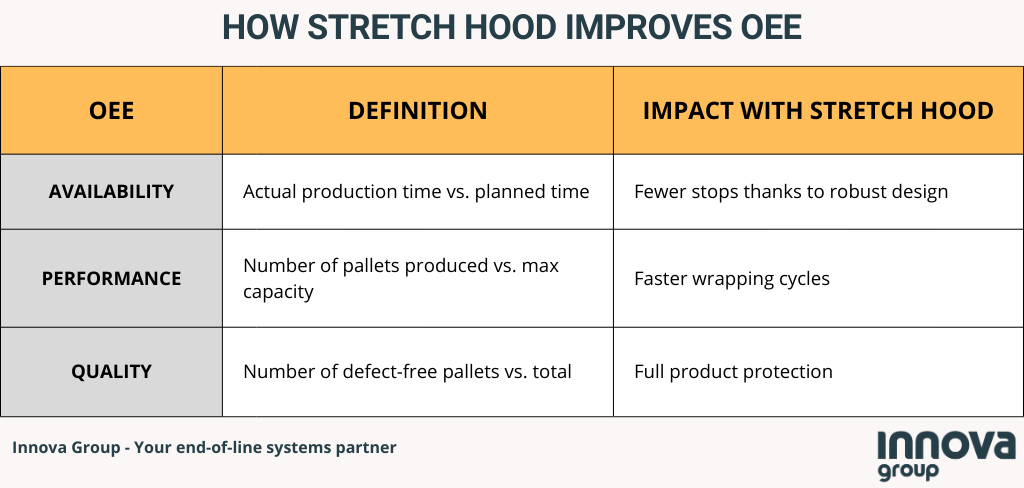

5. OEE (Overall Equipment Effectiveness)

OEE is a metric closely tied to the philosophy of continuous improvement, Lean methodology, and Industry 4.0. It is a key KPI to measure equipment efficiency by combining three key factors: availability, performance, and quality. The implementation of Stretch Hood has a direct impact on each of these parameters.

Practical OEE measurement:

- % OEE = Availability × Performance × Quality.

- Multiplying these three values gives a percentage reflecting the real efficiency of the end of the line. For example, with 87.5% availability, 83.3% performance, and 98% quality, the resulting OEE would be 71.5%.

KPI Indicator: OEE percentage.

Result: A packaging line with an OEE of 65% can reach up to 80% after the installation of Stretch Hood, thanks to reduced downtime, increased speed, and improved packaging quality.

6. ROI Improvement at the End of the Line

Finally, one KPI that is increasingly important in the industry: the Return on Investment (ROI) of acquired machinery or equipment. This is a fundamental KPI to evaluate the economic return of a packaging system.

How to measure this KPI in practice:

- % ROI = (Net savings / Initial investment) × 100

In reality, it can be considered a global indicator since it reflects the economic outcome of all other KPIs analyzed: savings on film consumables, reduction of logistics incidents, lower energy consumption, increased productivity, and OEE improvement. Each of these partial improvements generates an economic impact that, combined, results in a faster and measurable return on investment.

KPI Indicator: ROI percentage.

Result: The installation of a Stretch Hood system can be amortized between 6 and 12 months. The standard amortization calculation is always carried out in comparison with previous packaging systems (manual, semi-automatic, or automatic) and can vary greatly depending on the product, production volume, consumable expenses, or current packaging costs. For a precise ROI calculation, Innova offers a free savings study, analyzing the real payback of each packaging project.

End-of-line KPIs reflect the performance, efficiency, and sustainability of logistics operations. With Stretch Hood, companies can tangibly measure improvements such as reduced consumables, increased productivity, load stability, and sustainability. If you want to measure and improve the KPIs of your packaging line, Innova Group will advise you on how Stretch Hood technology can transform your end of the line. Contact our technical-commercial team and discover how we can help you optimize and improve your packaging line.