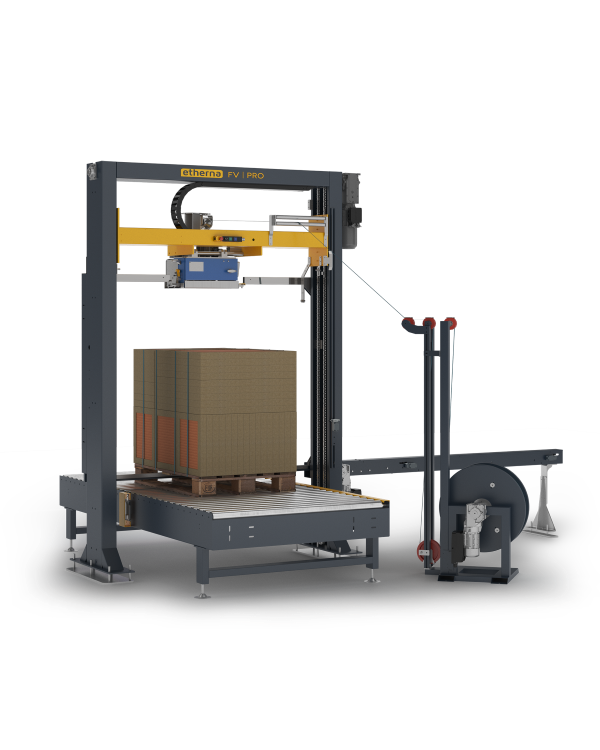

VERTICAL PALLET STRAPPING MACHINE

Stability and securing of palletized loads

Having trouble securing your pallets? Does your cargo need extra support in transit? Innova’s Vertical strapping system is one of the most versatile yet robust automatic solutions in the packaging line. It is designed to perform a strapping with maximum precision to secure the load with the pallet base.

Discover the advantages of Innova’s vertical strapper for pallets, with a wide range of accessories to adapt to the factory space, load protection complements and greater strapping precision.

Why the Innova Group' vertical strapping machine?

Maximum hold with 4-sided strapping

Innova’s vertical strapping machine offers greater support with a robust chassis that performs strapping on all 4 sides of the load. For this purpose, it includes a 90º pallet rotation system to perform vertical strapping in one or two directions.

Thanks to this feature, available in the accessories of the automatic strapping machine, greater stability and support of the load during handling and transport is achieved.

Strapping without load movement

Innova’s automatic strapping machine incorporates a Lateral Shift system to perform the strapping without moving the load. This saves space on the packaging line, in addition to providing greater stability and safety in industrial strapping.

This feature helps to secure and join the palletized load that is not fastened, and is used in the first workstations of the automatic packaging line.

Space saving with folding lance

Another feature designed to adapt the automatic strapping system in the factory is the folding lance. This is a flexible strapping lance structure, available as an accessory, which is placed in a vertical position prior to pallet strapping.

Pallet strapping systems are characterized by having a structure with several elements (strapping lance, decoiler, strapping frame, etc), so having a lance that can be vertically folded reduces space considerably, particularly for very wide pallet formats where a longer lance is required.

Proprietary patented strapping head

The vertical strapping system, like all of Innova’s automatic strapping solutions, includes the proprietary strapping head ODEN with patented technology.

The new strapping head provides greater accuracy for vertical strapping, thanks to its mostly electric design and torque control technology. It also includes fewer components, being sensorless while providing less maintenance.

Horizontal edge protector applicator

The pallet vertical strapper includes an automatic edge band applicator. One of the most popular accessories for strapping.

This system interposes horizontal edge protectors between the box and the strap to protect them and provide a better appearance and presentation of the load. It also serves to provide stability when removing the strapping at the point of sale.

Technical datasheet Vertical Strapping System

| Production capacity: | 60 pallets /hour |

| Operating nominal width: | Between 3/8"- 1/2″ - 5/8" (9 - 12 - 16 mm) |

| Strapping materials: | Polyester (PET) or Polypropylene (PP) |

| Maximum load dimensions: | Standard width: 47" // 1220 mm // Big formats: 80" // 2.050 mm |

| Maximum load height (from conveyor height): | Between 8" and 70" // 200 mm y 1.800 mm (adaptable to other loads) |

| Maximum load weight: | 4.400 lbs // 2.000 kg (adaptable to other loads) |

| Strapping head: | ODEN strapping head, resistance welded |

| Strapping uncoiler: | Motorized with buffer effect |