New EU Packaging and Packaging Waste Regulation 2024: How will it affect packaging films?

On 24 April, the European Parliament approved new measures to make packaging more sustainable and reduce packaging waste in the European Union (EU). This document will be formalised as a Regulation rather than a Directive. This means that once it is published, it will be applied in a harmonised manner throughout the EU, affecting the entire circulation of products within the European market, to boost the circular economy.

But how will this new regulation affect cargo packaging and what will happen to the existing taxes and regulations in Europe? In today’s article, we take a close look at what’s new in this regulation and how it affects final packaging and the use of film consumables.

What is new in the new EU Packaging and Waste Regulation?

The Packaging and Packaging Waste Regulation (PPWR) will apply to all materials, which means that it will have a major impact on the whole industry, as almost all products require packaging for transport.

The EU has been trying to fight plastic pollution for years. As early as 2018 it launched the European Plastics Strategy and subsequently created the plastic own resource taxes in 2021. A contribution system whereby each member country had to pay a levy of 0.80 euros per kilogram of non-recycled plastic packaging waste.

In several EU countries, there is currently a well-known plastic tax in place. For instance, Spain approved in 2023 a tax of 0.45 euros per kilogram of non-recycled plastic; in the UK, packaging with less than 30% recycled plastic is taxed at a rate of 210 pounds per tonne; and Portugal approved in 2022 a tax of 30 cents per non-reusable plastic packaging.

Currently, the new European regulation has introduced additional measures to further reduce the negative impact of plastic waste and promote environmental friendliness. Let’s take a closer look at these measures.

What’s new in the EU Regulation

The new regulations aimed at reducing the steady increase in waste include 5% packaging reduction targets by 2030, 10% by 2035, and 15% by 2040. EU countries are also required to significantly decrease the volume of plastic packaging waste.

As for manufacturers and importers, they will also have to minimise the weight and volume of packaging. In fact, the PPWR regulation has established a maximum allowable empty space percentage of 50% for grouped, transport, and e-commerce packaging. This will impact companies in their transportation and logistics operations.

Plastic related Bans from 2030

Certain types of single-use packaging will be banned from 1 January 2030. Unprocessed fresh fruit and vegetable packaging; single-dose sachets, such as those found for sugar and sauces in cafes and restaurants; single-dose toiletry sachets used in hotels and accommodation; and lightweight plastic bags smaller than 15 microns, will have to disappear from this date. In turn, the new rules set ambitious targets to reduce the use of single-use packaging in general. By 2030, 80% of beverage packaging should be reusable or recyclable.

Encouraging the recycling and reuse of packaging

According to the new Packaging and Packaging Waste Regulation, all packaging (except for light wood, cork, textile, rubber, ceramic, porcelain, and wax packaging), including plastic packaging, must be recyclable according to strict criteria.

In addition, ambitious targets for separate collections will be set. By 2029, 90% of single-use plastic and metal beverage containers (up to three litres) will have to be collected separately through deposit and return systems or other solutions to ensure that the collection target is met.

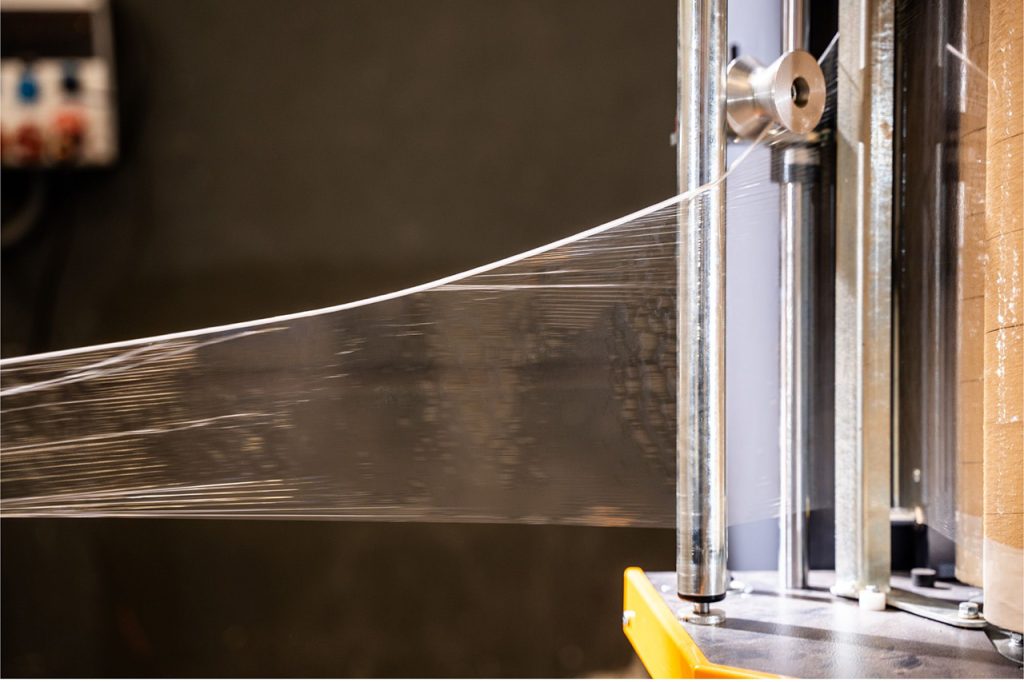

How does the new regulation affect packaging films?

We have seen the general changes the new regulation will require, but how will it affect packaging films and other packaging consumables? The new Regulation has also introduced significant changes in the packaging film industry, always intending to transition towards a more sustainable and circular model. Companies in the sector (both film manufacturers and packaging film users) will also have to adapt to the new packaging rules:

1. Increased recycled content:

The new measures adopted set minimum targets for recycled content for different types of packaging materials, including films. By 2030, PCR (Post-consumer Recycled) content should reach 30%, a figure that is difficult to achieve for many commercial films in 2024. This increased demand for recycled materials will also drive the creation of more efficient collection and recycling systems for packaging films.

2. Requirement for recyclable films:

From now on, to comply with current regulations, packaging films must be designed to be fully recyclable in their composition. The choice of materials, the structure of the film, and the presence of additives will be key aspects for this.

3. Mandatory labelling of recyclability

Under the new regulation, film companies will also be required to clearly label that the film is recyclable. Requiring companies to be more transparent and provide additional information on the environmental impact of their films, such as recyclability or recycled content, might encourage and promote research into developing new, more sustainable packaging films that fully comply with the new regulations.

How does it affect users and purchasers of packaging film?

The requirement for higher recycled content may increase the price of speciality films, which could translate into higher costs for the end user of the packaging. It remains to be seen how EU member governments will handle the new regulation, and whether it will affect the Single Use Plastic Tax and the 2021 plastic own resource.

It is also important to bear in mind that the actual impact of the PPWR will depend on many factors, such as the evolution of raw material prices, the implementation of the measures by governments and, the response of consumers.

The key to R&D and research in film: The case of Innova Group

In order to achieve the goals of the circular economy, collaboration is essential among various stakeholders including governments, film manufacturers, packaging machinery manufacturers, clients, and end users. That’s why at Innova, our R&D department has been searching for and testing films with higher recycled content. In recent years, our research has intensified with tests of advanced films of all types and the development of our packaging machinery:

- Testing of Stretch Hood films and lower micron Stretch Hood films to reduce the weight of the film.

- Testing of super stretch films (in case of Stretch Hood) to further reduce the amount of plastic in a stretch hood wrapping.

- Testing of films with up to 50% recycled content in different compositions and thicknesses.

- Programming of stretch hooding and stretch wrapping to reduce the amount of film used to a minimum.

- Development of the Stretch Hooding carriage to optimise the stretchability of films to their full potential.

- Development of machinery with more efficient components and motors, also to reduce energy consumption.

The actual impact of the Packaging and Packaging Waste Regulation will depend on various factors, including the changes in raw material prices, the proper implementation of the regulation by governments, and the market’s response. Therefore, research and development in the packaging industry will play a crucial role in meeting the new regulations and promoting more sustainable practices.

At Innova Group, with over 20 years of experience in manufacturing packaging systems, we provide expert advice on this subject and recommend you the best combination of packaging systems and packaging films to reduce your plastic consumption. Do not hesitate to contact us without obligation, we will be happy to assist you with your packaging needs.