Cerámica Utzubar modernizes its end-of-line with Innova’s Stretch Hood system

The Stretch Hood system has become one of the most popular packaging technologies in industries such as ceramics and construction, due to its benefits in product protection, pallet visibility, and overall cost savings compared to other systems. In this context, Cerámica Utzubar, a leading company in structural ceramics manufacturing in Spain, entrusted Innova Group to modernize its end-of-line with the Stretch Hood wrapping system.

The new Stretch Hood packaging line was recently installed at Utzubar’s plant in Etxarri-Aranatz (Navarra), where the company centralizes the production of bricks, blocks, and other construction materials. Cerámica Utzubar is a pioneer in sustainability within the sector, being the first company in Spain to produce its bricks using biomass instead of gas — a strong commitment to reducing emissions and caring for the environment. In this regard, the implementation of the Stretch Hood system reinforces this environmental strategy, replacing the gas-powered shrink wrapping process with a more efficient and sustainable Stretch Hood wrapping technology, fully aligned with Utzubar’s philosophy of responsible innovation.

The challenge: Upgrading the wrapping technology

Utzubar previously operated with a shrink wrapping system that, after years of use, required replacement. Among the company’s main challenges were the need to increase productivity with a faster and more efficient system, and to reduce packaging costs by eliminating gas consumption and optimizing film usage. Ultimately, Utzubar aimed to modernize its packaging line not only to improve its final pallet packaging but also to remain at the forefront of the construction ceramics industry.

Why switch from Shrink Wrapping to Stretch Hooding?

The Stretch Hood system proved to be the ideal alternative to traditional shrink hooding, as it significantly reduces energy costs by eliminating the use of gas and lowers film consumption through controlled film stretching. It also enhances workplace safety by removing the need for heat in the process.

Additional advantages include:

- Uniform, fully transparent wrapping that enhances product appearance and load stability.

- Greater versatility to handle different pallet heights and load formats.

- Increased hooding speed and continuous operation within the production line.

Overall, Stretch Hood provides a more economical, safe, and sustainable packaging solution, positioning itself as the natural replacement for traditional shrink systems in sectors such as ceramics and construction.

The solution: Stretch Hood integrated with the existing packaging line

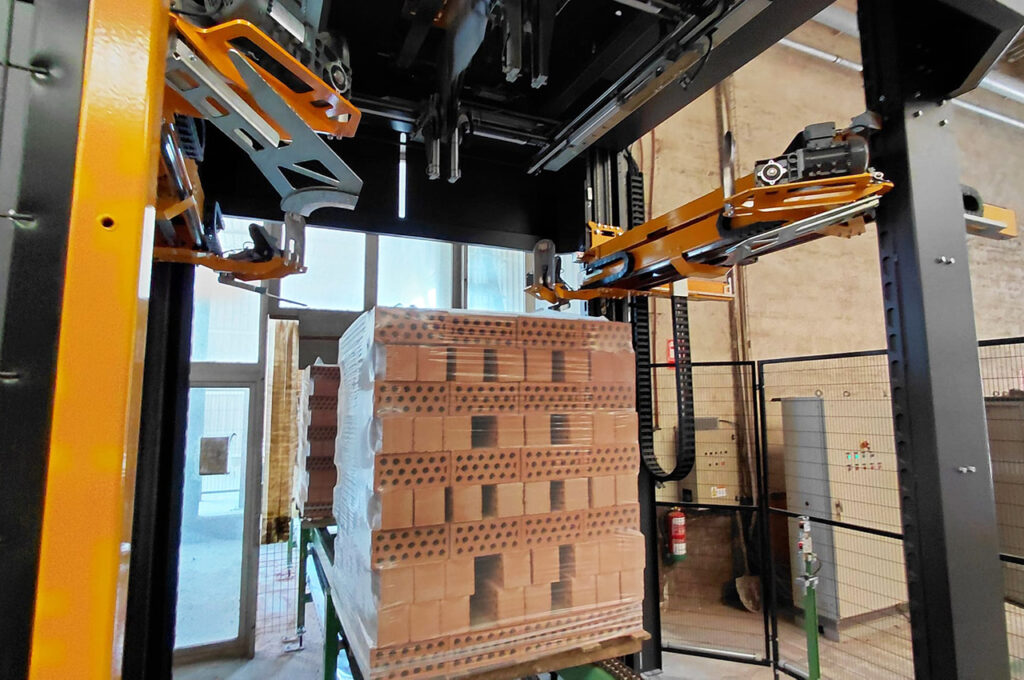

After analyzing Utzubar’s needs and requirements, Innova proposed the installation of a Stretch Hood system perfectly adapted to the existing end-of-line. The new Stretch Hood machine was integrated with the brick strapping unit already at Utzubar’s end-of-line. It was also connected to the current conveyor systems, achieving complete synchronization with Utzubar’s production flow.

The installed model, Stretch Hood SH | Pro, features a dual-reel system that enables automatic switching between different pallet formats, providing greater autonomy with fewer film reel changes. The system also delivers a higher wrapping speed, perfectly matching Utzubar’s production rate.

This project showcases Innova’s ability to tailor its packaging solutions to each client’s specific facilities, maximizing existing resources and delivering flexible, sustainable systems designed for long-term performance.

Project results for Utzubar

With the new installation, Utzubar has successfully reduced film consumption and eliminated gas usage, achieving a more economical and environmentally friendly packaging process. The company has also optimized its end-of-line performance by increasing productivity and line reliability, while improving operational safety and the overall appearance of the finished pallet with more uniform and professional protection.

The new line represents another step forward in Utzubar’s strong commitment to sustainability, reducing both the energy footprint and resource consumption in its packaging operations.

At Innova, we are proud to collaborate with leading Spanish companies such as Cerámica Utzubar, providing advanced packaging solutions that meet today’s market demands and contribute to the modernization of the building materials industry.

Thank you, Utzubar, for trusting in Innova’s technology!