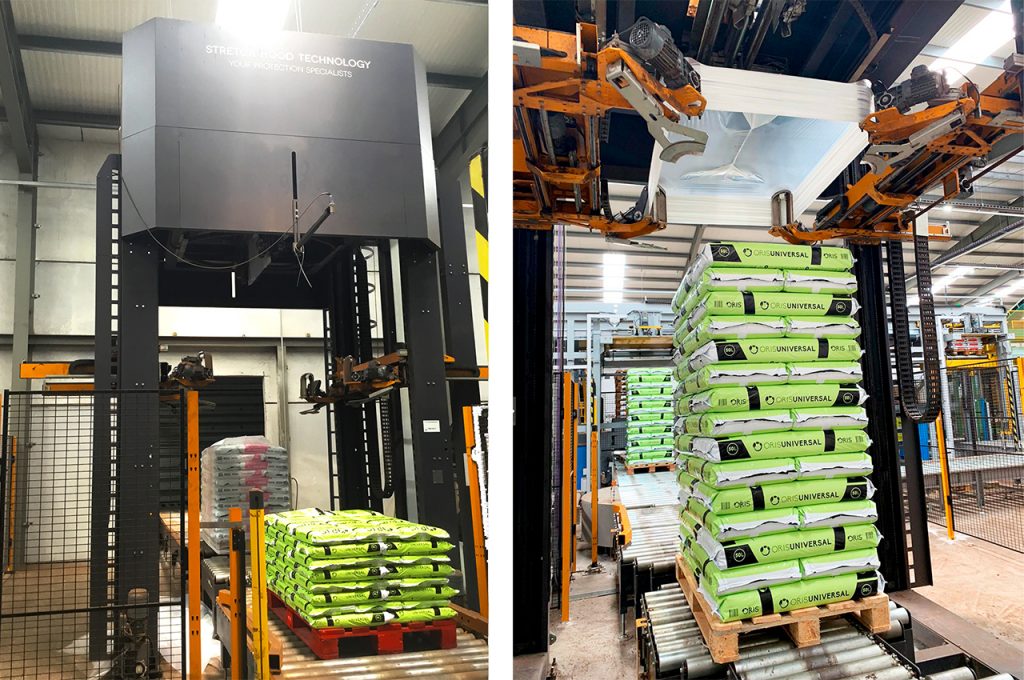

Case Study: Stretch Hood to protect substrate and compost products

Following our review of trends in logistics and industrial packaging we analyze today Stretch Hood for substrates, compost and fertilizer products. The Stretch Hood system has become one of the rapidly growing technologies for the protection of palletized bagged products. In fact, more and more manufacturers with bagged goods in the agrochemical sector are investing in this technology that combines protection, safety and efficiency. This is particularly the case of the substrates and fertilizers sector, where the Stretch Hood system is gaining ground and replacing systems such as stretch wrapping machines.

In today’s article we are going to unfold the keys of Stretch Hood for the product of substrates, fertilizers and derivatives, taking the example of our Portuguese customer Siro Fertilizantes, who since 2018 has a Stretch Hood line from Innova to protect its bagged product.

Comparison of bag protection systems

Why stretch hooding instead of pallet stretch wrapping? As manufacturers of both systems, many customers ask us this question, although the answer depends on the type of product. Both the Wrapper and Stretch Hooder have the same objective of protection and safety for transport, but the application and packaging process make their results different:

Stretch Wrapping system: by wrapping the load, it holds and protects it from the sides, however, it needs to apply a top cover to fully protect the product. Its main advantage is the versatility and wide range of stretch wrappers on the market, from semi-automatic solutions to high performance automatic stretch wrappers.

Stretch Hood System: this system wraps the load by means of a stretch hood film that adapts to the load, exerting pressure and holding it in place. The main advantage is that it is a tubular film that protects the product with a single layer, avoiding film excess and reducing costs.

The packaging process itself is one of the main reasons why agrochemical bag customers prefer Stretch Hood for efficiency, speed of packaging and above all total protection, among other advantages more specific to the sector.

LEARN MORE:

Comparative between packaging systems: Stretch Hood vs. Stretch Wrap

Advantages of Stretch Hood for substrates and fertilizers

For manufacturers of agricultural substrates and compost, the advantages of switching from Stretch Wrapping to Stretch Hood are decisive:

Total waterproof:

Due to the composition of the agricultural substrate, it is necessary that the product is watertight and protected from humidity and rain. The Stretch Hood system offers the best waterproof protection for the 5 visible sides of the load.

Protection against other factors:

For outdoor storage, Stretch Hood film also provides UV protection. This is a multilayer film, with barrier properties and additives for UV protection, anti-condensation, humidity, etc.

Compact and stable load:

Stretch hood wrapping is performed by stretching and adapting the film to the shape of the load. As a result, the bagged substrates remain compact in a single block and safe for transport. In addition, Innova’s Stretch Hooder system can reinforce the film at the base of the pallet to ensure that it is held in place during transport.

Adaptable to several formats:

One of the advantages of the stretch wrapping machine is the adaptability of the wrapping to different heights and sizes. Stretch Hood in this aspect is not far behind since the tubular film adapts to different heights. The Stretch Hooder system by Innova has two different film reels with automatic selection to adapt to different pallet formats. In this way we ensure that the load is protected with the correct size of film, minimizing the amount of film used.

Transparency and display:

One of the aspects valued by commercial substrate and compost companies is the flawless display of the product at the point of sale. With Stretch Hood, the film is completely transparent providing immediate brand recognition in gardening and agricultural stores.

Anti-theft security:

Related to the display of the load is the fact that Stretch Hood helps to detect and prevent theft attempts. The film is usually thicker and resists punctures and in case of tearing it leaves no room for concealment. On the other hand, with stretch wrapping, it is easier to conceal a theft with several layers of film.

Sustainability and plastic reduction:

Finally, another decisive factor for environmentally committed companies, such as Agro Products producers, is to obtain a higher energy efficiency and reduction of waste. Innova’s Stretch Hood System includes high-efficiency components and engines within an all-electric efficient system. The Stretch Hooder also reduces the amount of film used per pallet and film waste to a minimum. Nowadays there are several types of biodegradable and recyclable Stretch Hood film available in the market.

In short, the agrochemical sector is increasingly favoring advanced technologies and an example of this is the Stretch Hood system in their end of lines. Achieving a more protected, better displayed and safer product for transport, as well as a more sustainable process, is a great appeal for manufacturers of substrates and fertilizers.

At Innova Group we provide packaging consultancy according to the sector and objectives of the company. Contact us without obligation to make a Consumption and Feasibility Study of Stretch Hood for your product.