Challenges and Trends in the Logistics Sector for 2024: Full Digitalization, AI, and Sustainability

The world of logistics and packaging is facing an unprecedented time of change in 2024. The convergence of global challenges, technological innovations, and the pursuit of efficiency and increased productivity is redefining the industry’s operations in recent years. Challenges such as responding to supply chain agility, shortages of both skilled and unskilled labor, ongoing digital transformation, and the global sociopolitical landscape pose challenges that urge companies to seek disruptive solutions to remain competitive and sustainable.

Discover in our article the challenges that the industry faces and some of the solutions that many companies will have to adapt to remain competitive.

Challenges for 2024: Adapting to a Constantly Changing World

The packaging industry has undergone significant changes lately, beginning to have a profound impact on its day-to-day operations. The rapid pace of trade and continuous technological evolution demands much more agile and flexible supply chains. The shortage of workers, especially those skilled in these technologies, is driving the adoption of automation to optimize resources and processes. Continuous digital transformation and geopolitical challenges add additional layers of complexity, while political and commercial tensions affect supply chain stability.

Let’s take a look at some of these challenges coming in 2024 and the years ahead:

Supply Chain Agility

Large companies are advancing at breakneck speed thanks to constant technological innovation and changes in supply chain trends. Hence, the speed and agility of the global logistics sector itself will represent a major challenge for many medium-sized companies that must remain competitive in this digital world.

Global Labor Shortage

The lack of workers is a critical issue in the logistics and packaging industry. This problem is not only a lack of qualified labor in new technologies but also unskilled labor that no longer wants to perform routine or manual tasks. This issue ultimately affects costs, packaging and logistics processes, and the delivery of goods. The solution again lies in automation: machines are taking on roles in storage, automatic packaging, and even transportation.

Continuous Digital Transformation

Although digitization and automation are solutions to many logistic challenges, they are also a challenge in themselves as the market advances in leaps and bounds. Small and medium-sized enterprises must make an effort to digitize and optimize their packaging and logistic processes. In line with the previous point, they must also respond to the need to train their staff in these new technologies.

Sociopolitical Challenges

Political problems and disruptions in the supply chain, such as trade disputes or changes in international policies, remain key issues even if they do not seem apparent. Global uncertainty and sudden changes complicate logistics and force companies to adapt quickly to an unstable international environment.

With these challenges in mind, the logistics and packaging sector will face significant challenges in 2024, seeking innovative and strategic solutions to remain competitive and sustainable in a constantly changing world.

Logistics Trends and Innovative Responses:

The challenges outlined in the first part of the article delineate a complex landscape for the logistics and packaging industry in 2024. The sector is driven to adopt new technologies and trends in response to these challenges. These advancements aim not only to solve operational problems but also to radically transform the way they are managed.

1. Digitalization of All Logistics Processes

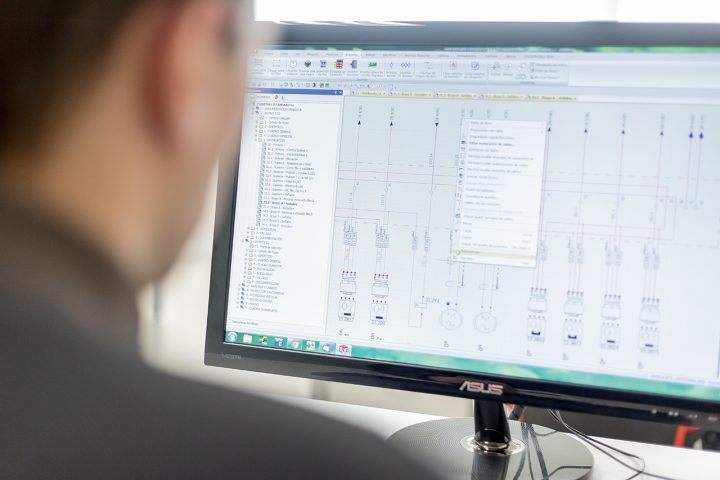

The ongoing emphasis on digitalization is leading to the incorporation of more automated and interconnected systems, such as intelligent warehouses or warehouses 4.0.

In the field of storage and logistics management, advances in the Internet of Things (IoT) and technologies such as RFID are allowing each product to be an interactive node, transmitting real-time data on location, status, and conditions. This information allows proactive problem anticipation and planning adjustments. Furthermore, automated data collection enhances decision-making, increasing productivity by up to 77%.

Regarding cargo packaging, the trend also leans towards having a 4.0 end-of-line that can provide real-time information on the entire packaging process (packaging, boxing, bagging, palletizing, and final pallet packaging). The introduction of 4.0 digital technologies also allows for greater optimization of packaging machinery and end-of-line systems, offering predictive maintenance and intelligent spare parts.

2. Total Logistics and Supply Chain Automation

In line with the first point, logistics automation, driven by automatic and connected end-of-line technologies and systems such as RFID and warehouse management systems, is optimizing processes such as storage and shipping of goods, reducing management costs by up to 30%.

The introduction of robotic automation and end-of-line systems in factories is transforming internal activities, such as product selection, palletizing, etc., driving efficiency and reducing labor and operational costs.

3. Agile Logistics and Artificial Intelligence (AI)

Another new trend is called “Agile Logistics,” which is the combination of innovative technologies such as artificial intelligence (AI), the Internet of Things (IoT), and predictive analysis. These new technologies or procedures enable optimization and streamlining of the supply chain through real-time analysis of each involved part.

Machine Learning (ML) is revolutionizing warehouse and inventory management by forecasting demand patterns and optimizing stock levels. The great advantage of these types of technologies is their ability to analyze large data sets, allowing unparalleled demand prediction, and offering greater agility and response to unforeseen events.

These AI and ML tools are also essential for optimizing real-time transportation routes based on traffic circumstances or other incidents, reducing the carbon footprint, and improving operational efficiency.

4. Sustainability and Eco-Logistics

Sustainability and eco-logistics are already business imperatives for companies, not just ethical considerations. The adoption of eco-friendly practices, such as biodegradable packaging, reduction of non-recycled plastic in packaging, and optimized routes to reduce emissions, adds efficiency to the supply chain.

In transportation, the integration of intelligent algorithms helps reduce routes and, consequently, the carbon footprint, while choosing vehicles with renewable energies and clean technologies reduces environmental impact.

As we have seen in several articles on the final packaging of loads, the industry is shifting towards more sustainable packaging systems that use less plastic and have more energy-efficient machinery.

5. More Sustainable Packaging Materials

The rise of e-commerce, digitalization of the supply chain, and environmental awareness have driven stricter regulations on packaging materials. The emergence of regulations and taxes on single-use plastics is driving innovation towards more sustainable materials, not only in primary packaging but also in load packaging.

Some examples and trends in more sustainable logistic packaging materials:

- Stretch Film or Stretch Hood with highly recycled components

- Stretchable paper consumable for automatic pallet wrappers

- Stretchable paper strapping

- Cardboard pallets for light loads

- Palletizing without pallets for sack loads, etc.

These are some examples of materials that the industry is adopting as more environmentally friendly alternatives. Also, updating and renewing packaging equipment plays a significant role in efficiency and sustainability, as it helps reduce consumables used.

In summary, 2024 marks an era of unprecedented innovation and challenges in logistics and packaging. As we have seen, upcoming trends and technologies present fundamental solutions to address challenges but also represent a challenge in themselves.

Undoubtedly, the changes we are experiencing will not only redefine how we operate but also lay the groundwork for a more efficient, adaptive, and environmentally conscious industry in the years to come.

From Innova Group, manufacturers with over 20 years of experience providing advanced end-of-line solutions and systems, we can accompany you in these automation and digitization changes in your logistics processes. Contact us without obligation, tell us about your project, and we will advise you.