Innova launches a redesigned horizontal strapping system to meet various industry needs

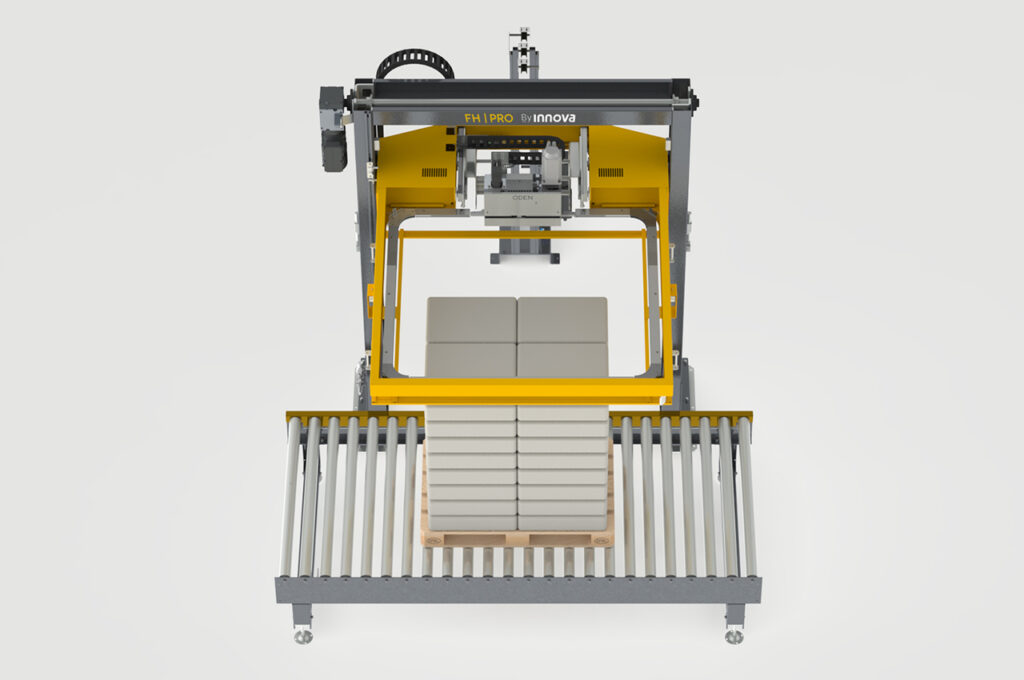

In response to market demands, Innova Group is unveiling a new automatic horizontal strapping system for pallets featuring a two-column structure. This model joins Innova’s horizontal strapping range as a functional and versatile solution, tailored to industries that require a less robust strapping system. The new model addresses the growing demand for a more compact and lightweight strapping system to secure loads that do not require additional compaction while maintaining the quality and precision that characterize Innova Group’s packaging systems.

The new two-column pallet strapper maximizes factory space and serves industries that require a simple, quick, and efficient solution for strapping light to medium loads.

Horizontal Strapping: Two Models for Different Applications

The new automatic strapping system becomes part of Innova’s Pro machinery line, maintaining technical features and performance comparable to other automatic pallet strapping systems. To better understand the advantages of the new two-column horizontal strapping system, it is essential to compare it with Innova’s original four-column model:

1. Four-Column Horizontal Strapper

The standard model of Innova’s four-column horizontal strapping system features a robust structure designed for heavy loads and large volumes, such as ceramic products, bricks, and other construction materials. This model stands out for its four-pillar, anti-vibration structure, minimizing load movement during the strapping process to ensure greater precision and packaging safety.

Additionally, it features an integrated load compacting system that straps and stabilizes heavy loads without needing additional accessories. This compacting feature is essential for industries handling heavy products that require block compacting to prevent box shifting during transport and ensure more uniform strapping.

2. New Two-Column Model

The new two-column horizontal strapping system is a lighter, more functional solution designed for industries requiring secure strapping without the robustness of the four-column model. Its two-column structure optimizes floor space and facilitates integration into production lines for industries such as food, where loads are typically lighter and more stable, or chemical, where packaging formats vary widely (e.g., boxes, drums, or jerrycans).

The absence of a load compactor supports businesses that value efficient and rapid packaging in a streamlined system, allowing for a customized automatic strapping solution with more straightforward operation. This model also adapts to different pallet heights and sizes, improving versatility compared to the four-column model in certain environments.

Advantages of the New Horizontal Strapping System

The new two-column horizontal strapping system provides many advantages for companies looking for a simple yet effective strapping solution:

- Strapping Without Extra Compaction: Designed for industries where load compaction is not required, this model provides secure strapping without the need for a compacting step, accommodating loads that only need to be fastened during transport.

- Focus on Load Stability: This strapping machine is optimized for the primary function of securing loads, offering a simple and effective solution without adding costly or maintenance-intensive accessories.

- Direct Pallet Loading and Unloading: Unlike other models requiring adjacent conveyors, this system allows for direct loading and unloading on the strapping machine, streamlining the packaging process and minimizing production line adjustments.

- Edge Protector Applicator Accessory: Although it is a simpler model, the two-column system can include an automatic edge protector applicator. These vertical edge protectors help stabilize the load into a single block, facilitating horizontal strapping while protecting the load and preventing shifting during transport.

Technical Features of the New Horizontal Strapping System

The new two-column horizontal strapping system retains the performance and reliability of Innova’s technology, consistent with other systems in the same range.

Key technical specifications include:

- Production Capacity: 60 pallets/hour

- Strapping Material: Polyester (PET) or Polypropylene (PP)

- Operational Strap Thickness: Between 9–16 mm

- Maximum Load Dimensions: 2050 x 1400 mm

- Maximum Load Height: 2000 mm (adjustable to other loads)

- Strapping Head: ODEN patented strapping head by Innova with resistance welding

- Strap Uncoiler: Motorized with a buffer system

- Available Accessories: Automatic edge protector applicator

Innova Group: A Comprehensive Range of Automatic Strapping Systems

With the launch of the two-column Strapping system, Innova Group expands its range of automatic strapping machines, reinforcing its commitment to innovation and responsiveness to specific market needs. Innova demonstrates its adaptability and customer-focused approach with this new system, which enhances the current lineup. It allows each client to choose the model that best meets their needs, whether they require the robust four-column system for securing heavy construction and ceramic products or the new two-column option for lighter loads.

The new horizontal strapping system joins a wide range of available strapping systems with their respective accessories:

- Horizontal Strapping System (Four Columns): With or without edge protector applicator

- Horizontal Strapping System (Two Columns): With or without edge protector applicator

- Vertical Pallet Strapping System: With or without edge protector applicator

- Four-Sided Vertical Pallet Strapping System: With or without edge protector applicator

- Vertical Strapping System for Boxes and Packets: For palletizing lines

In conclusion, with the launch of the new horizontal strapping system, Innova Group reaffirms its commitment to innovation and meeting the specific needs of each industry. For more information on how this system can be integrated into your production line or to learn about other packaging systems, don’t hesitate to contact our technical-commercial team, who will be delighted to advise you on a tailored packaging solution for your company.