Top 10 Frequently Asked Questions about the Packaging Line and their answers

When starting a packaging project, many questions arise about the configuration of the line, the adaptability to the production itself, connectivity and communications, etc. An end-of-line project, and in particular pallet packaging, has a great technical complexity with many particularities and elements to be agreed upon by the engineering departments of the manufacturer and the customer.

Without going into too much detail and technicalities, in this article, we have compiled the most Frequently Asked Questions (FAQ) that arise when approaching a new packaging project and their respective answers from our experience in a multitude of end-of-line projects.

Note: We define a packaging line as the end of the line after palletizing the product in its primary or secondary packaging. It is therefore the tertiary packaging line or pallet packaging, ready for storage and shipment.

The Top 10 FAQ of the Packaging Line

- What are the essential systems in a packaging line?

- How is the integration of the packaging line carried out?

- How many systems can be included in a packaging line?

- Can automatic and semi-automatic systems coexist on the line?

- Can the in-house conveyor line be used with new packaging systems?

- What are the standard dimensions of a Stretch Hood packaging line? How much space does it take up?

- Which pallet formats can the Packaging line handle?

- What type of vehicles and pallet transport are used in a packaging line?

- Which automation systems can a packaging line be connected to?

- Is the packaging line also part of Industry 4.0?

1. What are the essential systems in a packaging line?

A packaging line is composed of systems to protect and hold the product for transport and storage. It always includes at least one system that provides protection and support, such as the Stretch Hood or the Automatic Stretch Wrapper) If necessary, depending on the type of product and characteristics of the project, it also includes other fastening systems such as pallet strapping systems, wrapping machines for support, sealing system, etc.

2. How is the integration of the packaging line carried out?

In each project, it is necessary to study in detail the integration with the customer’s existing palletizing and production line. The engineering team evaluates, studies, and designs the line elements that best fit the customer’s needs, looking for an optimal connection and smooth flow.

Integration aspects of being taken into account for the integration with the end of the line:

- Location: facility space and dimensions, environment, and temperatures.

- Safety perimeters: safety fencing and signaling.

- Pallet infeed and outfeed flow: conveyor and lifting systems.

- Pallet transport vehicle movement flows.

- Connectivity and communication: with production line, logistics warehouse, etc.

- Production specifications: pallet formats, infeed and outfeed flows

- Connection and intervention of other systems: labeling, weighing, etc.

3. How many systems can be included in a packaging line?

It is possible to integrate, a priori, all packaging systems that the customer demands or that the project requires. The limit is the facility space. Once again, the Technical Engineering department looks for the best combination of the necessary systems, prioritizing the final packaging objectives and space optimization. Even if the customer requests more systems, each project is studied to see their need according to the fundamental objectives.

For example:

- To respond to a high production rate, it is recommended to have double packaging systems or systems with high-speed accessories. For instance, a high production line may require a double strapping system and a high-speed Stretch Hood wrapping system.

- To adapt to the available floor space, a conveyor line is designed to transfer the pallets between the different packaging systems in the smallest possible space. For this purpose, additional conveyors are used, such as rotating conveyors, elevators, 90º transfer conveyors, etc.

- To meet the requirements of fastening the load, sometimes the customer requires more strapping or wrapping systems, but the engineering department can dismiss the need or recommend the use of a system as a substitute for another, as happens with the automatic wrapping machine that sometimes replaces the strapping.

4. Can automatic and semi-automatic systems coexist on the line?

In principle, the automatic packaging line is designed to fully automate the end of the line, but there are occasions when the customer’s facility or production can continue to use semi-automatic systems.

When defining a line project, a pallet flow is designed in which everything from the input to the output after the final stretch hooding is automatic. To guarantee productivity, it is not recommended to “stop” this process to include a semi-automatic system in the middle of the line. But there may be some exceptions where there are manual or semi-automatic systems before or after the packaging line, the most common being pallet transport vehicles.

Some examples of the co-existence of automatic and semi-automatic systems:

- Semi-automatic pallet entry into the line, either by pallet truck or forklift. In this case, there is a semi-automatic element, since the operator must input the pallet data to be packed on the control panel. When the entry is made by AGV, the same vehicle communicates the format to the PLC of the line automatically.

- Sealing, manual strapping, or stringing after palletizing and before the packaging line: when minimum stability of the pallet is required for the transport of the pallet to the line, manual or semi-automatic systems are used to perform this pre-packing.

- The output of the pallet by forklift or pallet truck is similar to the indeed entry of the pallet.

- Pallet weighing or labeling system excluded from the packaging line. In this case, the transport to this station should be semi-automatic.

5. Can the in-house conveyor line be used with new packaging systems?

Whenever required by the client, we try to ensure that the new packaging line is as compatible as possible with the existing conveying systems. If this is a renovation of the installation and the existing conveyor line is in good condition and meets the requirements to adapt to the new systems, it could be used. Another type of adaptation would be to connect the line to the existing conveying system through connection and elevation systems.

6. What are the standard dimensions of a Stretch Hood packaging line? How much space does it take up?

If we are referring to Innova’s Stretch Hood system only, the line can be located in installations with a smaller footprint than usual. In addition to the fact that the Stretch Hood machine is designed to occupy as little space as possible, the conveyor line can be adapted as much as possible to the customer’s facilities, using the connection, rotation, and elevation systems, as mentioned in previous questions.

7. Which pallet formats can the Packaging line handle?

Although this is one of the most frequently asked questions, the answer differs greatly from case to case. At Innova, our standard packaging line with Stretch Hood is designed for the most standard pallets in several sectors such as construction, ceramics, chemical, agrifood, etc. We work with minimum pallet measures of 32 x 24 inches (800 x 600 mm), a maximum of 80 x 55 inches (2000 x 1400 mm), and heights up to 100 inches (2.500 mm). If you have a different size or very different pallets, please contact us without commitment and we will study the feasibility of your project according to the packaging systems that your production needs.

8. What type of vehicles and pallet transport are used in a packaging line?

In a total end-of-line automation project, it is common to include AGVs / LGVs (Automatic Guided Vehicles) used to transport pallets from the palletizing line to the packaging line and from there to the logistics warehouse. Even so, it is very common for this type of vehicle to coexist with semi-automatic vehicles, such as forklifts with drivers or motorized pallet trucks.

Innova’s packaging line is prepared for access by all types of transport vehicles, using ground-level transport systems for pallet trucks or roller conveyors adapted to AGV infeed.

9. Which automation systems can a packaging line be connected to?

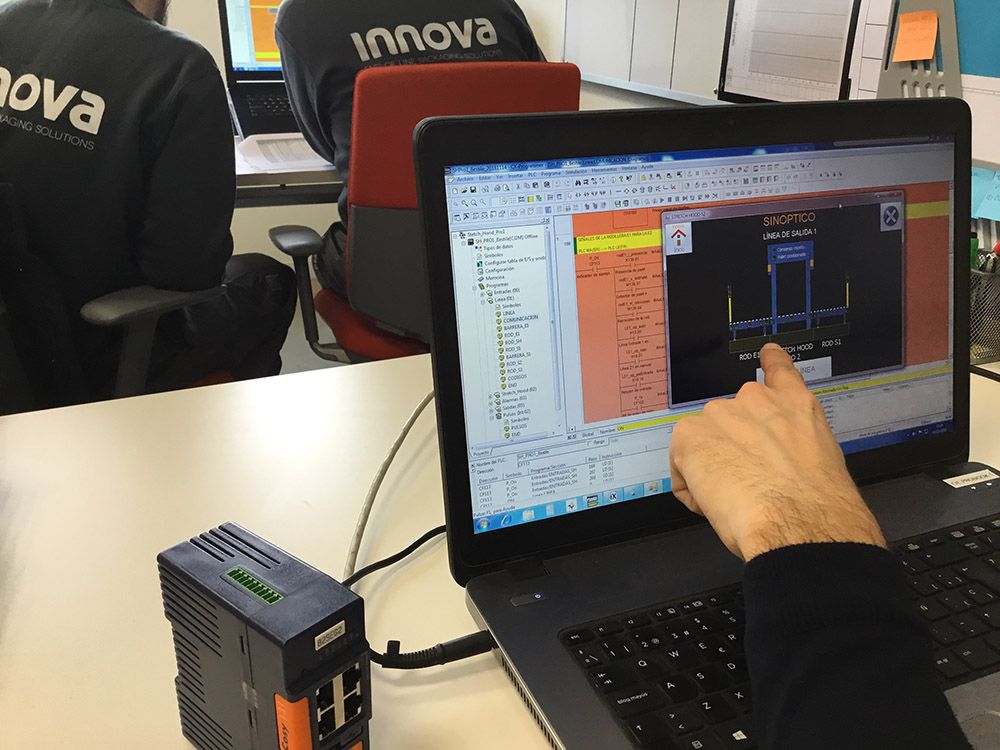

In a packaging line project, it is essential that the packaging line communicates and agrees with the existing system. In the case of Innova’s line, we connect with the most common PLC systems. We offer integrations and compatibility with PLC systems such as Omron, Siemens, Rockwell, or Schneider.

Check without commitment the compatibility with the system of your factory.

10. Is the packaging line also part of Industry 4.0?

Yes, packaging, like any factory production process, is an element of Industry 4.0. Packaging automation is an essential step towards Industry 4.0 since most of the packaging systems are already interconnected with the production system and ERP of the company.

In the case of Innova’s packaging line, we have intelligent components that offer performance reporting, remote connection to the line, fault diagnosis, and predictive maintenance of wear and possible repairs.

In short, all questions must be clarified at the time of the definition and design of the packaging line project. At Innova, our Engineering and Technical-Commercial Consulting teams study every detail and requirement to achieve optimal, efficient, and high-quality packaging.

Do not hesitate to ask any questions regarding your packaging project, we will be more than pleased to answer them.