What are the best packaging systems for protecting building material loads?

When transporting or storing building materials like bricks, tiles, concrete blocks, panels, or other heavy products, it is crucial to select the optimal packaging system for each type of product. Good protection of these materials not only ensures the integrity of the product, but this process can also improve your company’s profitability by preventing material losses and accidents. Based on our experience as manufacturers of packaging systems, in this article, we will analyze the characteristics and advantages of the most commonly used systems in the building industry to optimize the entire logistics process and ensure that materials are kept in perfect condition.

What are the packaging objectives of the construction industry?

Before discussing the top packaging systems for the construction industry, it’s important to note that this sector has distinct goals related to safeguarding materials during transportation and storage, optimizing costs, promoting sustainability, and enhancing efficiency in logistics processes.

1. Protection and security of materials: This industry specializes in using heavy and fragile materials, such as roof tiles or masonry bricks. To guarantee that items arrive in perfect condition at their final destination, it is essential to protect them effectively during transportation and storage, thus preventing any losses.

2. Automation and optimization of operating costs: Efficiency and time reduction in the packaging process translate into significant savings for any building materials manufacturer company. The construction sector is progressively embracing automated solutions to cut down on time and packaging material costs while ensuring load quality and protection. One such innovative solution is the Stretch Hood Packaging, which is becoming increasingly popular in the market.

3. Logistics efficiency: Any company in the sector aims to optimize its operations to meet the high demands of the market in terms of deliveries and logistics requirements. Packaging systems that ensure the stability of loads and facilitate their handling and transport are essential to comply with this.

4. Sustainability Goals: The construction materials industry is working towards becoming more sustainable and environmentally friendly, aiming to minimize its carbon footprint. This can be achieved through packaging solutions that minimize the use of plastic and other non-recyclable packaging materials, as well as technologies that reduce energy consumption and CO2 emissions, such as the Stretch Hood system, one of the most sustainable packaging technologies.

Now that we understand the objectives and challenges of this industry, let’s explore the optimal packaging systems to address them.

Which packaging system is best to protect building materials?

Depending on the company’s protection and security objectives, the chosen system will be different. Here, we will demonstrate which packaging systems are best suited for this industry.

1. Automatic Strapping Systems

Pallet Automatic strapping systems are one of the most widely used solutions for securing construction material loads that do not require protection from external agents. This is the case with bricks, tiles, and other materials, where the product is stacked without being previously boxed or packaged. Let’s see the advantages of each strapping system for this type of load:

- Horizontal strapping: Essential for compacting and securing loads horizontally, thus avoiding possible displacements and falls during transport. For this industry, Innova offers one of the most robust automatic horizontal strapping machines on the market, featuring a 4-pillar anti-vibration structure for greater stability to ensure safer strapping of heavy construction loads without incidents.

- Vertical strapping: The vertical strapping system provides additional support for high loads, providing stability and full support to the base of the pallet for transport and storage. A very useful method for stacking materials and still guaranteeing the firmness of the pallet.

Strapping systems have the characteristic of being highly adaptable, as they allow the position and number of straps to be configured depending on the size of the load to guarantee its securing. In addition, they also have the ability to apply edge cardboard protectors to make the load more secure and avoid possible damage to the material caused by the tension of the strap itself.

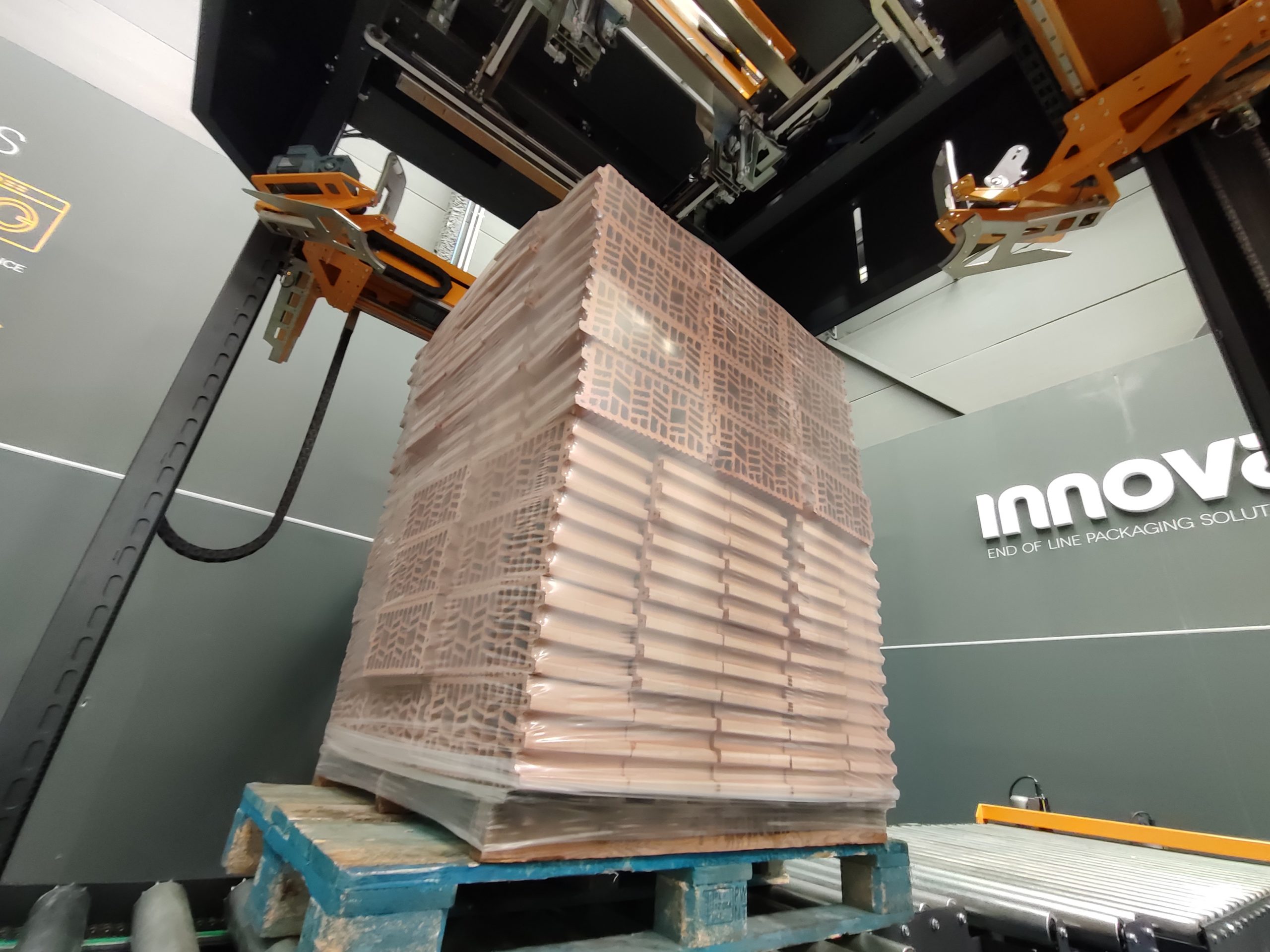

2. Stretch Hood System

Although several packaging systems on the market offer excellent protection for building material loads, at Innova, as experts in packaging systems, we would like to highlight the Stretch Hood system above all others.

This type of wrapping system guarantees the best protection for any type of load thanks to the tubular hood and the characteristics of the Stretch Hood film, which provide water tightness and protection for the material against external agents such as dust, humidity, and other elements.

One strong advantage of the Stretch Hood is its status as the fastest packaging system, capable of wrapping up to 120 pallets per hour. The wrapping finish with Stretch Hood is also an aspect to highlight. The completely transparent film, free of any creases or wrinkles, ensures excellent visibility of the brand and legibility of codes, thereby increasing the product’s value.

In addition, the Stretch Hood is a highly efficient and environmentally friendly solution, reducing consumables and energy costs by up to 50%, thus aligning with the sustainability goals of the construction industry.

3. Shrink-Hood system

The shrink hood system is a viable packaging solution for the building materials industry as an alternative to the Stretch Hood. This system, comprising an automatic hooding machine and a film-shrinking oven installation, offers a high level of load protection and sealing.

The Shrink Hood System adapts completely to the contour and shape of the pallet, as the film adheres to the pallet with the application of heat, protecting it from external agents. This allows the load to be more securely fixed to the pallet, making it easier to transport and handle. It is important to note that while it may not be as efficient as the Stretch Hood, it provides automated and optimized packaging, wrapping up to 60 pallets per hour.

Discover the differences between the Stretch Hood and the Shrink-Hood systems in our comparative article:

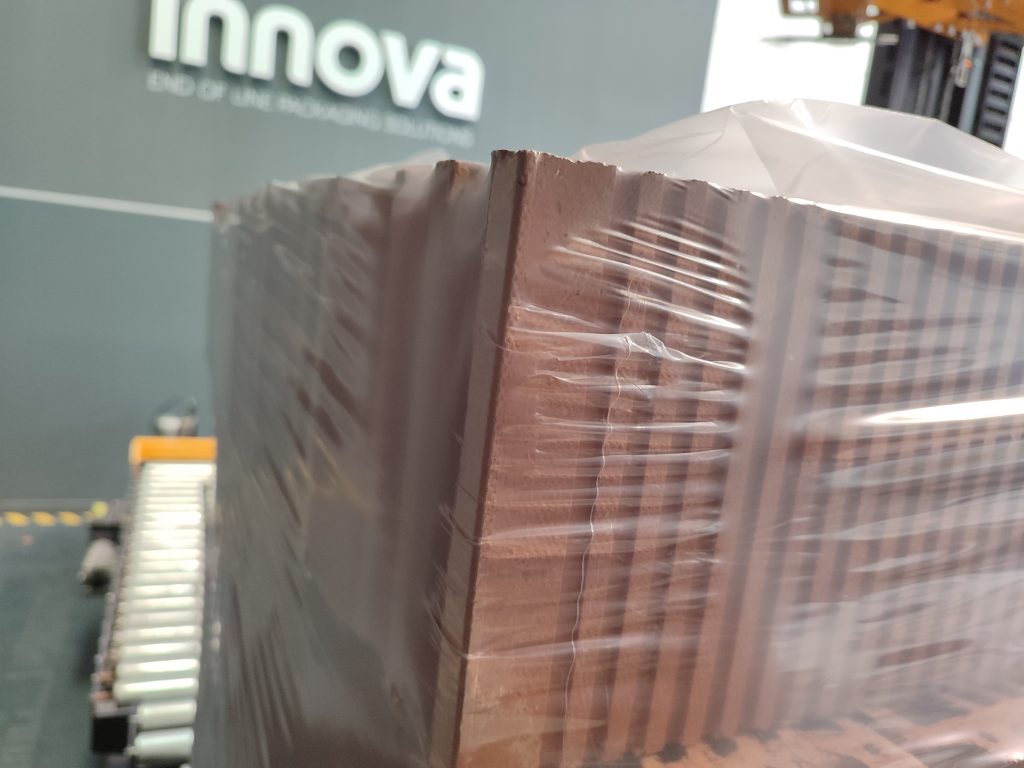

4. Stretch Wrapping Systems

Automatic pallet stretch wrappers are a very good solution for the construction industry due to their capacity to wrap heavy and large pallets typically in this industry. A system that ensures uniform protection around the entire load, while reducing the risk of damage during transport and storage.

It should be noted that some wrapping systems, as in the case of Innova’s, also offer the option to add extra accessories such as a top cover applicator and edge protectors to enhance its protection. The automatic stretch wrapper also stands out for its elastic roping device or reinforcement cord system, which offers an extra fixation to the load similar to the strapping application.

The two most common wrapping machine systems used in this industry are the Ring Stretch Wrapper and the Arm Stretch Wrapper.

In summary, choosing a suitable packaging system is a must for protecting building materials during transport and storage. The most advanced systems, such as the Stretch Hood or Automatic Wrapping Machines, offer great solutions that ensure the integrity and total security of the loads while optimizing logistical processes and reducing costs. It should also be noted that all these systems not only protect the products but also contribute to the efficiency and sustainability of the building materials industry.

At Innova Group, with over 20 years of experience in manufacturing packaging systems, we offer expert advice on selecting and optimizing your end-of-line equipment. Contact us without obligation and discover how we can optimize your logistics and supply chain with efficient and safe packaging.