How to protect loads of different heights and sizes with Stretch Hood

In an increasingly demanding logistics industry, many manufacturers are opting for higher formats because of their benefits in terms of efficiency and space optimization. However, when it comes to transporting goods of great heights, it is crucial to ensure their safety and protection, as they present risks of slipping, falling, or damage during transport. To solve these problems, there are several pallet packaging systems widely used in the market, such as stretch wrapping, stretch hooding, strapping systems, etc. In this context, the Stretch Hood packaging system presents itself as more than just an alternative solution, standing out for its advantages in protection and high adaptability to different sizes and heights.

Join us in today’s article in which we will unravel the keys to Stretch Hood and other systems to protect goods of different sizes and heights.

Why stack the goods at great heights?

Many manufacturers opt for staking their loads in considerably high formats for their end-of-line storage and productivity advantages:

1. Space optimization:

Stacking pallets to high heights maximizes the utilization of available space in the warehouse and on the conveyors, allowing more products to be transported in less space. This is especially important in environments where space is limited and you are looking to make the most of every square meter.

2. Logistics efficiency:

It improves logistical efficiency by reducing the number of trips handling in-plant loads or pallets required. In addition, a higher load allows for greater loading capacity in containers and other transport vehicles.

3. Cost savings:

By having higher loads, the number of pallets is reduced, but also the number of shipping containers, resulting in savings in packaging consumables and transportation costs. By maximizing storage space, we also avoid the use of additional warehousing facilities, resulting in medium- to long-term savings.

4. Increased end-of-line productivity:

Palletizing higher loads also increases productivity in final packaging by reducing the overall number of pallets. In addition, a well-secured and protected high load can speed up the loading and unloading process, which in turn improves the overall productivity of the supply chain.

It is important to keep in mind that while high load stacking offers benefits in space optimization and logistical efficiency, it also presents challenges in terms of the stability and safety of the goods. Therefore, it is essential to have adequate packaging systems to ensure security and stability during transport.

Stretch Hood or Stretch Wrapping system for high loads?

Historically, the stretch wrapper has been the system of choice for protecting all types of loads. When it comes to high loads, the pallet stretch wrapper can make multiple wraps around the load to contain and secure the product and reduce the risk of drops during transport. However, in recent years the Stretch Hood system has emerged as more of an alternative due to its various advantages of increased protection and adaptability to the load. Some of the key features of the Stretch Hood:

- The Stretch Hood film: Stretch Hood film is a highly technical film with a multilayer MLLDPE (linear low-density polyethylene) composition that offers total protection and impermeability to the load, with a highly extensible material adaptable to different sizes and shapes.

- Reduction and savings on film: The Stretch Hood system allows significant savings in film consumption compared to the pallet stretch wrapper. According to Innova Group’s estimates, the Stretch Hood reduces the amount of film used in each package by 50%. This not only lowers costs but also has a positive impact on the environment by reducing the amount of plastic.

- Greater factory autonomy: Unlike the stretch wrapper, which requires frequent film changes due to the size of the reels, the Stretch Hood does not require as many changes, as a single reel would allow 1,000 pallets to be hooded, as opposed to 300-400 pallets for the stretch wrapper. This translates into greater efficiency in the production line and less downtime.

Which system is best suited to different sizes within the same production?

Both the Stretch Hood and the pallet Stretch Wrapper can adapt to different load sizes within a single production run. However, there are differences in the way each system achieves this adaptability.

The Stretch Hood excels in its adaptability with less film, as it uses an elastic tubular film that adjusts to the size of the load. This means that a single reel of film can be adapted to different dimensions, providing flexibility and production efficiency.

On the other hand, the stretch wrapper can also adapt to different sizes but requires more film wraps to achieve it. Each time the format or contour of the goods is changed, it is necessary to adjust the number of wraps and layers of film to properly secure the load on the pallet. This implies a higher film consumption and a not-so-fast process compared to the Stretch Hood.

How to wrap different sizes and heights of loads with Stretch Hood

The major advantages of the Stretch Hood lie in the type of stretch hooding of the loads, the technical characteristics of the stretch hood machine itself, and also in the composition of the Stretch Hood film itself.

“Super Stretch” film

Stretch Hood film is characterized by its high stretchability to handle loads of varying heights, offering safe and stable protection. But in recent years, film manufacturers have also been investing time in improving the formulas and composition of this type of film to give it greater elasticity and stretching capacity. Thus we find in the market “Super Stretch” films that can wrap loads of different lengths or sizes.

Film reel-holder system

Most Stretch Hood systems can include 2 reels of film, and in the case of manufacturers such as Innova also allow 3 reels of film, or even 6 reels in new Stretch Hood developments. The greater the number of reels, the greater the number of film formats to accommodate different load sizes. This capacity is a requirement of industries with a high variability of formats such as household appliances, food, logistics, picking, etc.

Stretch Hood adaptability

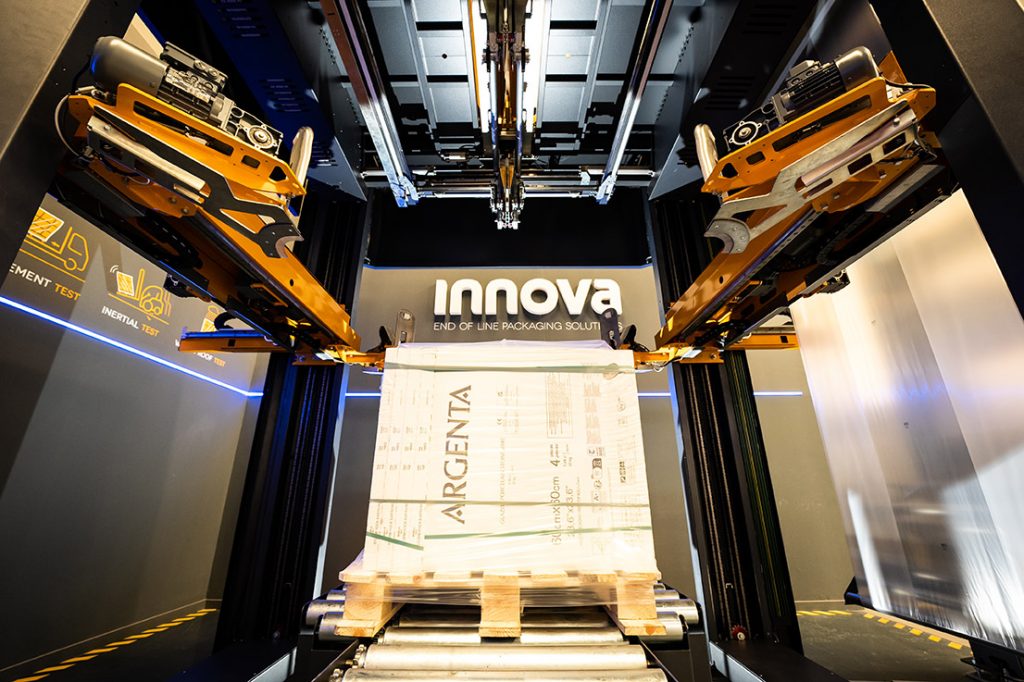

While Stretch Hood is a relatively new packaging technology, it is constantly evolving with numerous advances that have been developed over the past few years. An example of this is Innova’s Stretch Hood system. This innovative system offers a greater degree of adaptability to wrapping at different heights.

In conclusion, when it comes to protecting loads of great heights, it is essential to have an adequate packaging system. Having a packaging partner that studies each project in detail, considering factors such as containment, safety, efficiency, and material savings, is highly recommended.

At Innova Group, with hundreds of end-of-line installations around the world, we can advise you on how to best protect your palletized loads. Contact us without obligation and we will carry out a study of your project to determine which packaging system and finish best suits your product.