How to Achieve the Most Efficient Strapping with Innova’s Patented Strapping Head

How can we ensure a more precise and error-free automatic strapping process? How can we reduce breakdowns and maintenance for strapping machines? Strapping plays a crucial role in load stability and securing, and one of the most frequently used and worn-out components in automatic strapping systems is the strapping head.

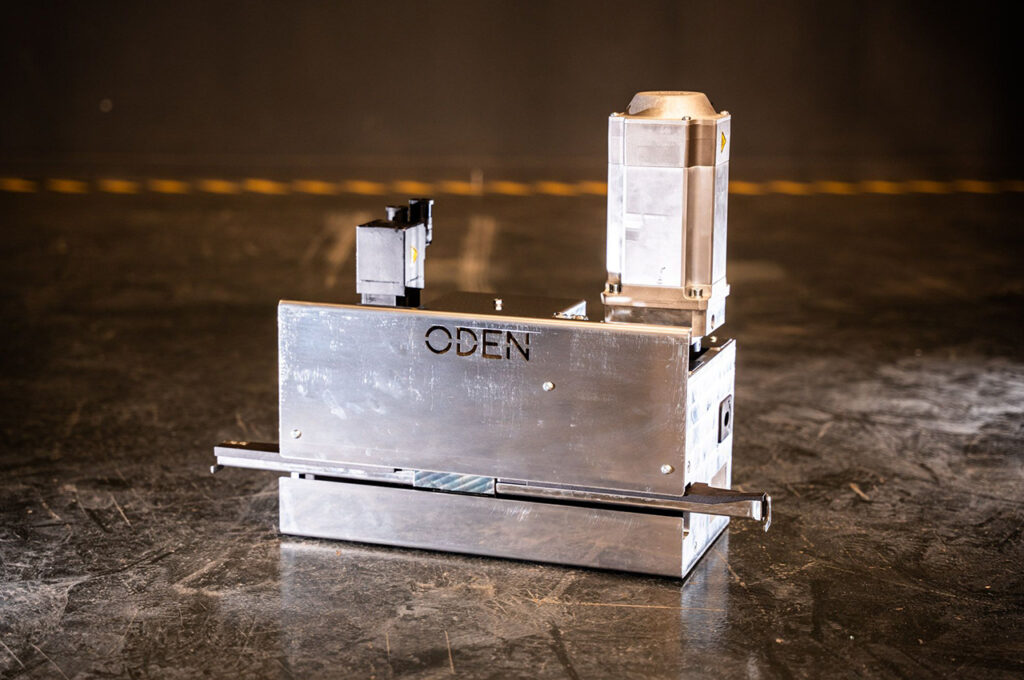

At Innova, we deeply understand the demands of industrial strapping. Since 2021, we have been developing and manufacturing our own patented, compact, and modular strapping head. This innovative system is designed for greater efficiency and productivity, ensuring optimal performance.

The Strapping Head: The Core of the Strapping System

Strapping heads are one of the components that experience the most wear and tear in an automatic packaging line. Performing thousands of strapping cycles daily, this central piece of pallet strapping machines often requires frequent maintenance and repairs.

For this reason, one of the key objectives in developing Innova’s ODEN head was to design a more compact, lightweight system with fewer components—eliminating clutches and sensors to minimize breakdowns and reduce maintenance costs.

Why Choose Innova’s ODEN Strapping Head?

The ODEN head was named after precision, strength, durability, adaptability, and high performance—qualities inspired by Norse mythology. Customers using Innova’s strapping systems confirm the significant advantages ODEN offers in terms of efficiency and strapping quality:

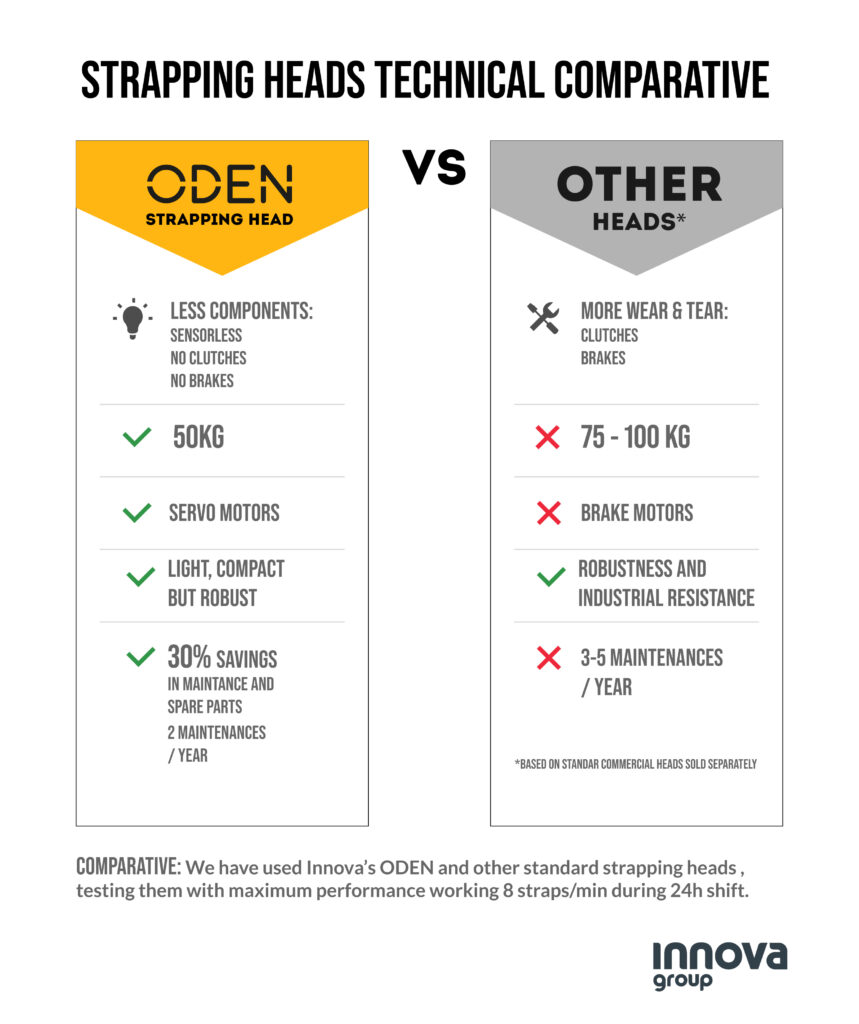

- Reduced wear and breakdowns – Unlike traditional heads that incorporate clutches, sensors, and brakes prone to wear and tear, ODEN utilizes the latest electronic control technology. It features two servo motors, one with positioning control, eliminating mechanical components susceptible to failure and significantly reducing maintenance costs. Additionally, it has fewer pulleys, reducing the risk of strap jams.

- Superior energy efficiency – Thanks to its lightweight yet robust design, ODEN consumes less energy than other market alternatives, optimizing efficiency without compromising strap tension strength.

- High connectivity and adaptability – ODEN easily integrates into automated strapping systems, ensuring real-time traceability and control for maximum operational efficiency. It also adapts to a wide range of products, formats, and industries, offering outstanding versatility when choosing a strapping system.

- Speed and precision in strapping – Its torque control technology enables a faster and more precise operation, reducing cycle times and increasing packaging line productivity. In the event of a strap misfeed, ODEN’s intelligent strap arrival detection system allows for retraction and retrying. Furthermore, it offers controlled stop functions for accurately measuring strapping distances.

How Does ODEN Compare to Other Market Strapping Heads?

Innova’s ODEN head offers significant advantages over standard market strapping heads, making it a highly sought-after component—even for strapping systems not manufactured by Innova.

Compared to similar strapping heads, ODEN stands out for:

- Eliminating Wear-Prone Components – ODEN removes traditional clutch and stop brake components, replacing them with a servo motor with positioning control. This significantly reduces maintenance and extends equipment lifespan.

- Lighter and More Compact Design – ODEN is 33% lighter and 46% smaller than similar high-performance heads. Its lightweight design also optimizes energy consumption, making it more efficient than heavier alternatives.

- Increased Speed and Accuracy – The servo motor ensures a more uniform and controlled strap application, reducing common errors found in traditional mechanical systems.

- Quick Installation – The strapping head is easy to install and connect to both the strapping system and the packaging line, ensuring a faster and cleaner installation than other solutions.

- Lower Maintenance Costs – Maintenance costs are 30% lower due to fewer replacement parts and reduced component wear.

- Quieter Operation – Compared to other strapping heads, ODEN operates with significantly less noise, contributing to a quieter and safer working environment in factories.

The Smart Strapping Head for the Factory of the Future

Innova’s strapping head not only revolutionizes strapping efficiency and durability but also integrates Smart technology for optimized packaging management.

Thanks to its connectivity, ODEN allows real-time monitoring of strapping cycles, enabling predictive maintenance to prevent breakdowns before they occur. It can track key data, such as the number of daily strapping cycles and machine performance indicators (e.g., stops, errors), allowing automated performance reports to be sent to customers.

Additionally, ODEN features a remote access system, allowing real-time diagnostics and technical support, reducing downtime, and improving overall productivity.

Currently available in Innova Systems—Soon Beyond

Innova Group’s strapping systems come standard with the ODEN head, ensuring superior application performance. Additionally, the ODEN strapping head can operate independently thanks to the control system developed by Innova Group, enabling easy integration into various automatic packaging systems in the industry. This has been a key requirement from many customers familiar with Innova’s strapping systems and ODEN heads who wish to upgrade their existing systems or incorporate them into development of different strapping solutions.

Currently, the ODEN strapping head is available in all Innova strapping solutions:

- Two-column horizontal strapping system

- Four-column horizontal strapping system

- Vertical strapping system

- Box strapping system

In summary, choosing ODEN means investing in innovation, efficiency, and reliability in industrial strapping. With its patented technology, lower operational costs, and productivity-enhancing design, ODEN sets new standards in the packaging industry.

Want to learn more about ODEN, our automatic strapping systems, or other industrial packaging solutions? Contact our technical team today—we’re happy to assist you!